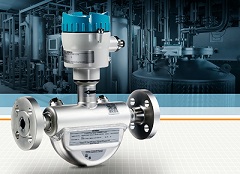

With Sitrans FC410, Siemens presents the lightest and most compact Coriolis flowmeter currently available, featuring a high measuring accuracy of 0.1 percent. With dimensions of only 265(L) x 280(H) x 90(B) millimeters and a weight of 4.6 kilograms in the smallest version (DN 15), the meter is ideal for machine and plant construction or for frame-mounted equipment. The combination of compact design, high accuracy, IP67 degree of protection and a wide variety of functions orients Sitrans FC410 toward use in almost any facility, even where space is very limited.

With Sitrans FC410, Siemens presents the lightest and most compact Coriolis flowmeter currently available, featuring a high measuring accuracy of 0.1 percent. With dimensions of only 265(L) x 280(H) x 90(B) millimeters and a weight of 4.6 kilograms in the smallest version (DN 15), the meter is ideal for machine and plant construction or for frame-mounted equipment. The combination of compact design, high accuracy, IP67 degree of protection and a wide variety of functions orients Sitrans FC410 toward use in almost any facility, even where space is very limited.

With the new Mini Flow Link (MFL) concept, Siemens has succeeded in accommodating transmitter functionalities in the sensor. The digitally based MFL permits a much more compact design without additional assembly work. Sitrans FC410 is therefore flexible enough for installation in confined spaces without any compromise in measuring accuracy or reliability. The digital MFL features a very fast signal update of 10 milliseconds and provides not only flow rate data but also the mass, volume, density, and temperature of the medium. The innovative CompactCurve design of the sensor developed by Siemens ensures a high level of reliability due to its stable zero point, low pressure loss, and high immunity to process noise and plant vibrations. Sitrans FC410 is therefore especially suitable for use in challenging applications where accuracy and reliability in measurements of density and mass are required. The flowmeter also works at pressure levels of up to 100 bar and temperatures of -50 to +200 degrees Celsius without any loss of measuring accuracy. Sitrans FC410 is certified for use in the pharmaceutical as well as food and beverage industries according to the most important standards, such as 3A, EHEDG and FDA.

Sitrans FC410 communicates with Simatic and all other common process control systems via the multidrop-addressable Modbus RTU485 and can be integrated easily into both existing and new systems.Installation and commissioning of the flowmeter require only simple, one-time configuration in the control system with little programming. If a flowmeter is replaced or further flowmeters are connected, the user's settings are automatically transferred.

For further information on Sitrans coriolis flowmeter

Air Jordan VII 7.5 Ture Flight

Endress+Hauser will acquire US company Kaiser Optical Systems. Regulatory authorities in the United States have approved the former parent company, Rockwell Collins, to complete the transaction already announced in August. The acquisition is effective from 22 November 2013.

Endress+Hauser will acquire US company Kaiser Optical Systems. Regulatory authorities in the United States have approved the former parent company, Rockwell Collins, to complete the transaction already announced in August. The acquisition is effective from 22 November 2013. The International Society of Automation (ISA) announces that it is accepting applications for its wide range of 2014 educational scholarships, which will be awarded to college and university students who demonstrate outstanding potential for long-range contributions in the fields of automation, instrumentation and control.

The International Society of Automation (ISA) announces that it is accepting applications for its wide range of 2014 educational scholarships, which will be awarded to college and university students who demonstrate outstanding potential for long-range contributions in the fields of automation, instrumentation and control. Yokogawa Electric Corporation announced today that it has been selected as the Main Automation Contractor for Chevron Phillips Chemical Company LP's (Chevron Phillips Chemical) USGC Petrochemicals Project. The project was first announced in March 2011 and will include a 1.5 million metric tons/year (3.3 billion pounds/year) ethane cracker and two new polyethylene facilities, each with an annual capacity of 500,000 metric tons (1.1 billion pounds).

Yokogawa Electric Corporation announced today that it has been selected as the Main Automation Contractor for Chevron Phillips Chemical Company LP's (Chevron Phillips Chemical) USGC Petrochemicals Project. The project was first announced in March 2011 and will include a 1.5 million metric tons/year (3.3 billion pounds/year) ethane cracker and two new polyethylene facilities, each with an annual capacity of 500,000 metric tons (1.1 billion pounds). Invensys, a leading supplier of state-of-the-art industrial software, systems and control equipment to the world’s major industries, has rendered a multi-year, multi-million dollar corporate license to SK innovation.

Invensys, a leading supplier of state-of-the-art industrial software, systems and control equipment to the world’s major industries, has rendered a multi-year, multi-million dollar corporate license to SK innovation. The Allen-Bradley Stratix 5900 services router is the first in the Rockwell Automation network product portfolio to deliver virtual private network (VPN) and firewall capabilities simultaneously. These capabilities make the router well-suited for securing cell/area zones, as well as connecting to a cell/area zone from a remote location over an untrusted network.

The Allen-Bradley Stratix 5900 services router is the first in the Rockwell Automation network product portfolio to deliver virtual private network (VPN) and firewall capabilities simultaneously. These capabilities make the router well-suited for securing cell/area zones, as well as connecting to a cell/area zone from a remote location over an untrusted network. Process plants and pipelines generate thousands of alarms from their automation systems every day – many of which are not serious. Control room operators must then quickly distinguish between routine process alarms and critical alarms that warn of operating problems or safety issues.

Process plants and pipelines generate thousands of alarms from their automation systems every day – many of which are not serious. Control room operators must then quickly distinguish between routine process alarms and critical alarms that warn of operating problems or safety issues. National Instruments (Nasdaq: NATI) today announced NI VeriStand 2013, the latest version of its configuration-based software environment with an open, intuitive interface for developing real-time testing applications. NI VeriStand software provides a common test framework capable of spanning the entire embedded software development process with test component reuse for consistency across each phase. The 2013 release features direct integration with NI DIAdem data management software, providing automated postprocessing and report generation. Engineers can configure automation scripts and report templates in DIAdem and operators can easily log data, perform postprocessing and generate reports with just one click for a high-quality test process.

National Instruments (Nasdaq: NATI) today announced NI VeriStand 2013, the latest version of its configuration-based software environment with an open, intuitive interface for developing real-time testing applications. NI VeriStand software provides a common test framework capable of spanning the entire embedded software development process with test component reuse for consistency across each phase. The 2013 release features direct integration with NI DIAdem data management software, providing automated postprocessing and report generation. Engineers can configure automation scripts and report templates in DIAdem and operators can easily log data, perform postprocessing and generate reports with just one click for a high-quality test process. Advantech WebAccess is a web browser-based software package for human-machine interfaces (HMI) and supervisory control and data acquisition (SCADA). All the features found in conventional HMI and SCADA software including Animated Graphics Displays, Real-time Data, Control, Trends, Alarms and Logs, are available in an standard web browser. WebAccess is built around the latest internet technologies. The basic components are:

Advantech WebAccess is a web browser-based software package for human-machine interfaces (HMI) and supervisory control and data acquisition (SCADA). All the features found in conventional HMI and SCADA software including Animated Graphics Displays, Real-time Data, Control, Trends, Alarms and Logs, are available in an standard web browser. WebAccess is built around the latest internet technologies. The basic components are: