The International Society of Automation (ISA) has announced that it will begin developing a new certification program as part of a recently announced $23 million federal grant to fund two-year degree programs in “Mission Critical Operations” at five North Carolina colleges.

The International Society of Automation (ISA) has announced that it will begin developing a new certification program as part of a recently announced $23 million federal grant to fund two-year degree programs in “Mission Critical Operations” at five North Carolina colleges.

The grant, administered through the US Department of Labor, is designed to prepare tomorrow’s workforce to compete for increasingly demanding, high-wage and high-skill jobs in industrial operations and information technology, particularly those defined as mission critical—“operations requiring round-the-clock supervision of systems” and those “aimed at combating the evolving threat of critical infrastructure operations failure.”

ISA’s new Certified Mission-Critical Professional (CMCP) certification program will test graduates based on the skills and body of knowledge taught through new Mission Critical Operations curriculum and degree programs to be established at Cleveland Community College, Wake Technical Community College, the University of North Carolina at Charlotte, Nash Community College and Moultrie Technical College.

While Mission Critical Operations encompasses a broad spectrum of career areas—including infrastructure maintenance, communications and emergency operations—ISA’s new CMCP certification program will focus on industrial operations, such as automation engineering technology, advanced manufacturing, and cybersecurity of industrial control networks.

More than half of the $23 million grant is allocated to Cleveland Community College, the grant consortium leader in North Carolina and a long-time workforce development partner of ISA and ISA’s sister organization, the Automation Federation. Nearly $1.5 million of the remaining amount will finance ISA’s development of the CMCP certification program.

“As an organization that has been training and certifying professionals for rewarding careers in automation, engineering and manufacturing for decades, ISA is uniquely capable to develop this new CMCP certification program,” says Dalton Wilson, ISA’s manager of Education Services. “Furthermore, our existing, long-standing partnership with Cleveland Community College will be a major asset as we work with educators there to craft a certification program that’s directly tied to the curriculum and degrees to be offered at the five colleges.”

Since the functions, skills and knowledge requirements of a Mission-Critical Professional in industrial operations and the precise coursework essential to train one are not yet well defined, Wilson says it will take time to develop the CMCP certification program. Based on the grant proposal, the first full year the program will be offered will be 2017.

“A comprehensive job analysis needs to be conducted, and we’ll be identifying and engaging subject-matter experts to assist in developing the certification exam,” he reports. “Once completed, the CMCP certification will be another valuable addition to our certification offerings and, when combined with a degree in Mission Critical Operations, graduates in this field will be able to really differentiate themselves among prospective employers and significantly enhance their marketability.”

Air Jordan V High Supreme

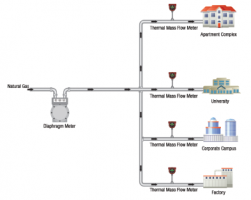

Unlike oil, natural gas exists in abundance in the United States. Of the natural gas consumed in the United States in 2011, 95% was produced domestically. The U.S. Energy Information Administration projects U.S. natural gas production to increase from 23.0 trillion cubic feet in 2011 to 33.1 trillion cubic feet in 2040, a 44% increase. Almost all of this increase in domestic natural gas production is due to projected growth in shale gas production, which will grow from 7.8 trillion cubic feet in 2011 to 16.7 trillion cubic feet in 2040. This natural gas boon highlights the importance for utility companies to provide homes, businesses, and mid-to-large size facilities with accurate natural gas billing. Traditionally, utility companies have used diaphragm meters to measure natural gas usage, which is then charged to customers on their monthly energy bill. Although diaphragm meters are a trusted billing mechanism by utility companies, they may not provide customers with the most accurate natural gas bill. Diaphragm meters have limitations in natural gas measurement. If the diaphragm meter does not accurately measure the natural gas, this can result in utility companies overcharging customers.

Unlike oil, natural gas exists in abundance in the United States. Of the natural gas consumed in the United States in 2011, 95% was produced domestically. The U.S. Energy Information Administration projects U.S. natural gas production to increase from 23.0 trillion cubic feet in 2011 to 33.1 trillion cubic feet in 2040, a 44% increase. Almost all of this increase in domestic natural gas production is due to projected growth in shale gas production, which will grow from 7.8 trillion cubic feet in 2011 to 16.7 trillion cubic feet in 2040. This natural gas boon highlights the importance for utility companies to provide homes, businesses, and mid-to-large size facilities with accurate natural gas billing. Traditionally, utility companies have used diaphragm meters to measure natural gas usage, which is then charged to customers on their monthly energy bill. Although diaphragm meters are a trusted billing mechanism by utility companies, they may not provide customers with the most accurate natural gas bill. Diaphragm meters have limitations in natural gas measurement. If the diaphragm meter does not accurately measure the natural gas, this can result in utility companies overcharging customers.

At the SPS/IPC/Drives trade fair, Kontron announced the launch of a new control cabinet IPC product family for automation. The new Kontron KBox IPCs have been designed for industrial control applications and offer outstanding scalability from entry to high-end level. All four new systems feature an industrial-grade design for common control cabinet installations, are available long-term and can be fitted with industrial I/Os, fieldbuses and/or Industrial Ethernet interfaces to meet individual requirements. Owing to the modular construction with Kontron standard components, the processor portfolio is highly scalable for individual design requirements and at all times up-to-date. Suppliers of automation equipment and OEM customers in machinery and plant engineering thus profit from particularly efficient customization options based on standardized building blocks.

At the SPS/IPC/Drives trade fair, Kontron announced the launch of a new control cabinet IPC product family for automation. The new Kontron KBox IPCs have been designed for industrial control applications and offer outstanding scalability from entry to high-end level. All four new systems feature an industrial-grade design for common control cabinet installations, are available long-term and can be fitted with industrial I/Os, fieldbuses and/or Industrial Ethernet interfaces to meet individual requirements. Owing to the modular construction with Kontron standard components, the processor portfolio is highly scalable for individual design requirements and at all times up-to-date. Suppliers of automation equipment and OEM customers in machinery and plant engineering thus profit from particularly efficient customization options based on standardized building blocks. ASCO Numatics, the world's leading manufacturer of comprehensive fluid automation, flow control, and pneumatics solutions, has introduced a mobile app for iPhone and Android Devices. By searching "ASCO Flow Calculator" within either the Apple iTunes or Google Play store, the user is able to download the mobile app at no charge. This app features the ASCO Flow Calculator, which enables users to quickly calculate flow for a valve or determine the Cv needed to properly size a valve. Additionally, the Fluid Guide provides reference information on the types of valves available for most common corrosive and non-corrosive gases and liquids.

ASCO Numatics, the world's leading manufacturer of comprehensive fluid automation, flow control, and pneumatics solutions, has introduced a mobile app for iPhone and Android Devices. By searching "ASCO Flow Calculator" within either the Apple iTunes or Google Play store, the user is able to download the mobile app at no charge. This app features the ASCO Flow Calculator, which enables users to quickly calculate flow for a valve or determine the Cv needed to properly size a valve. Additionally, the Fluid Guide provides reference information on the types of valves available for most common corrosive and non-corrosive gases and liquids. Yokogawa has announced that its subsidiary, Yokogawa Middle East & Africa, has received an order from Petroleum, Chemicals & Mining Company Limited*1 (PCMC) to supply the control system for the SWRO-4 Desalination Plant, which is being built in Jubail, Saudi Arabia by the Power & Water Utility Company for Jubail and Yanbu (Marafiq).

Yokogawa has announced that its subsidiary, Yokogawa Middle East & Africa, has received an order from Petroleum, Chemicals & Mining Company Limited*1 (PCMC) to supply the control system for the SWRO-4 Desalination Plant, which is being built in Jubail, Saudi Arabia by the Power & Water Utility Company for Jubail and Yanbu (Marafiq). Advantech’s new ECU-1871 is Intel Atom D510 Energy Controller with 2 x LAN, 3 x COM, IRIG-B,and it has been designed to be the most flexible energy controller available. With IEC-61850 compliance, the ECU-1871 is a highly reliable, flexible and stable controller which makes it ideal for all power automation and renewable energy needs.

Advantech’s new ECU-1871 is Intel Atom D510 Energy Controller with 2 x LAN, 3 x COM, IRIG-B,and it has been designed to be the most flexible energy controller available. With IEC-61850 compliance, the ECU-1871 is a highly reliable, flexible and stable controller which makes it ideal for all power automation and renewable energy needs. The International Society of Automation (ISA) has announced that it will begin developing a new certification program as part of a recently announced $23 million federal grant to fund two-year degree programs in “Mission Critical Operations” at five North Carolina colleges.

The International Society of Automation (ISA) has announced that it will begin developing a new certification program as part of a recently announced $23 million federal grant to fund two-year degree programs in “Mission Critical Operations” at five North Carolina colleges. Asahi Kasei Synthetic Rubber Singapore Pte. Ltd. (AKSS), a subsidiary of Asahi Kasei Chemicals Corporation, has built a plant on Singapore’s Jurong Island that produces 50,000 tons per year of solution-polymerized styrene-butadiene rubber (S-SBR), a type of synthetic rubber that is used in green tires to improve fuel efficiency and performance. As the demand for S-SBR is rapidly growing due to increasingly strict environmental regulations and rising awareness of environmental issues, Asahi Kasei Chemicals has made it a priority to accelerate production of this key material.

Asahi Kasei Synthetic Rubber Singapore Pte. Ltd. (AKSS), a subsidiary of Asahi Kasei Chemicals Corporation, has built a plant on Singapore’s Jurong Island that produces 50,000 tons per year of solution-polymerized styrene-butadiene rubber (S-SBR), a type of synthetic rubber that is used in green tires to improve fuel efficiency and performance. As the demand for S-SBR is rapidly growing due to increasingly strict environmental regulations and rising awareness of environmental issues, Asahi Kasei Chemicals has made it a priority to accelerate production of this key material. The Fieldbus Foundation today announced the latest updates to its open, non-proprietary FOUNDATION™ fieldbus technical specifications. The new features will enhance the usability of FOUNDATION technology, with the ultimate goal of making the digital fieldbus automation experience easier than conventional analog control systems.

The Fieldbus Foundation today announced the latest updates to its open, non-proprietary FOUNDATION™ fieldbus technical specifications. The new features will enhance the usability of FOUNDATION technology, with the ultimate goal of making the digital fieldbus automation experience easier than conventional analog control systems.