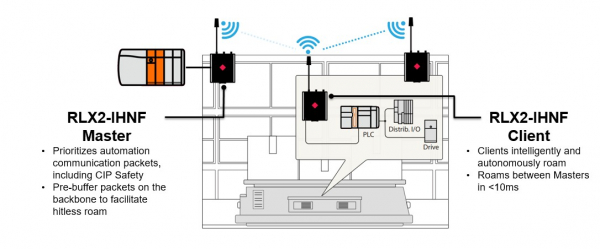

Beyond improving quality, uptime, and productivity, functional safety is often a requirement in applications leveraging mobile robotics. While local proximity sensors, E-Stops, safety zones, and safety curtains are often used in AMR applications, a SIL 2 or SIL 3 safety rating for the AMR system as a whole requires the use of a SIL 3-rated safety protocol like CIP Safety or PROFIsafe.

Beyond improving quality, uptime, and productivity, functional safety is often a requirement in applications leveraging mobile robotics. While local proximity sensors, E-Stops, safety zones, and safety curtains are often used in AMR applications, a SIL 2 or SIL 3 safety rating for the AMR system as a whole requires the use of a SIL 3-rated safety protocol like CIP Safety or PROFIsafe.

Both CIP Safety and PROFIsafe follow the “black channel principle,” which is described in IEC 61508. The black channel principle specifies that two safety devices must have enough intelligence, and enough diagnostics in their communications, to ensure the communication network between the safety devices has zero impact on the ability of the safety device to detect communication errors. In other words, safety protocols like CIP Safety and PROFIsafe have error detection mechanisms built within the safety protocol itself. These error-detection mechanisms consist of time stamps to ensure packets are not lost, delayed, repeated or out of order, and various identifiers and diagnostics to authenticate and validate the messages.

While the safety protocol and safety devices host the intelligence to ensure the safety of the application, there is a risk that a network device, like a wireless Ethernet radio, could have a negative impact on the timing requirements within the error detection mechanism. In a CIP Safety system, the timing expectation is defined by the Requested Packet Interval (RPI), the Timeout Multiplier, and the Delay Multiplier. In a PROFIsafe system, the timing expectation is defined by the F-Monitoring or PROFIsafe Monitoring time. Regardless of which protocol is being deployed, it is important to configure these parameters to meet both your functional safety requirements and your uptime requirements.

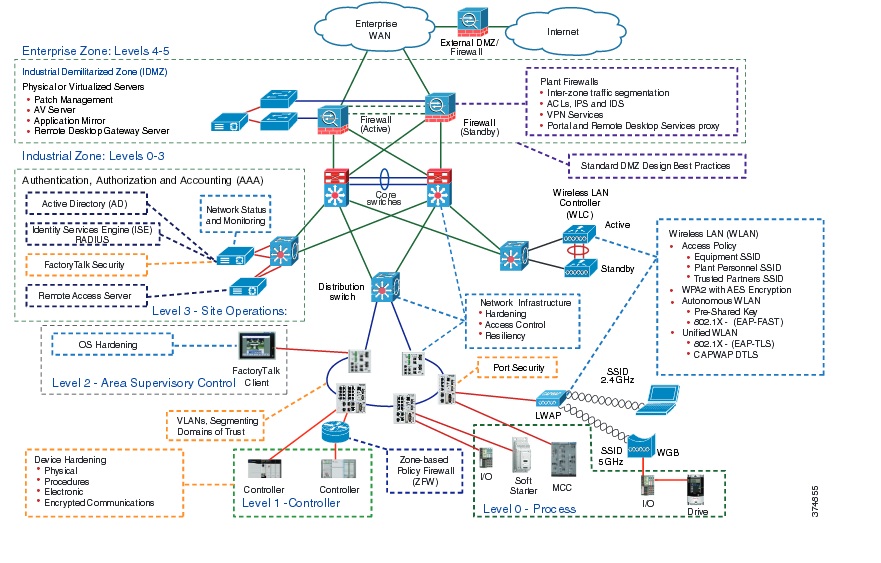

Many manufacturers segment business-system networks from plantwide networks by using an industrial demilitarized zone (IDMZ). But once segmented, how is data from industrial automation and control systems (IACS) securely shared across this buffer zone?

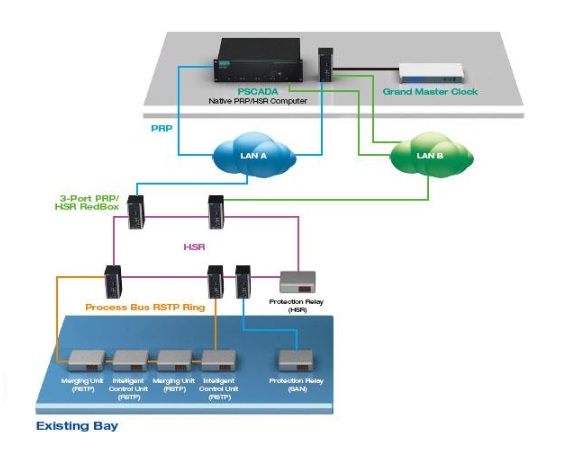

Many manufacturers segment business-system networks from plantwide networks by using an industrial demilitarized zone (IDMZ). But once segmented, how is data from industrial automation and control systems (IACS) securely shared across this buffer zone? In this paper, Moxa examine existing substation topologies and possible integral and scalable methods to achieve efficient redundancy with PRP (parallel redundancy protocol) and HSR (high-availability seamless redundancy). An optimized IEC 61850 PRP/HSR architecture should provide scalable integration for easy modification of functionalities and extension of the substation. Upgrading SANs (single attached nodes) and DANs (dual attached nodes) to a PRP/HSR network will require an efficient and cost effective solution in order to construct a seamless/bumpless communication infrastructure to ensure maximum system availability.

In this paper, Moxa examine existing substation topologies and possible integral and scalable methods to achieve efficient redundancy with PRP (parallel redundancy protocol) and HSR (high-availability seamless redundancy). An optimized IEC 61850 PRP/HSR architecture should provide scalable integration for easy modification of functionalities and extension of the substation. Upgrading SANs (single attached nodes) and DANs (dual attached nodes) to a PRP/HSR network will require an efficient and cost effective solution in order to construct a seamless/bumpless communication infrastructure to ensure maximum system availability. When building a machine, skid or industrial application, engineers often re-use IP addresses. Network address translation (NAT) is a methodology that enables this without introducing a duplicate IP address error into the plantwide architecture. A new white paper from Cisco and Rockwell Automation, “Deploying Network Address Translation within a Converged Plantwide Ethernet Architecture,” provides guidance and validated architecture designs to help engineers deploy NAT for one machine or skid, or for an entire cell or area zone in a plant.

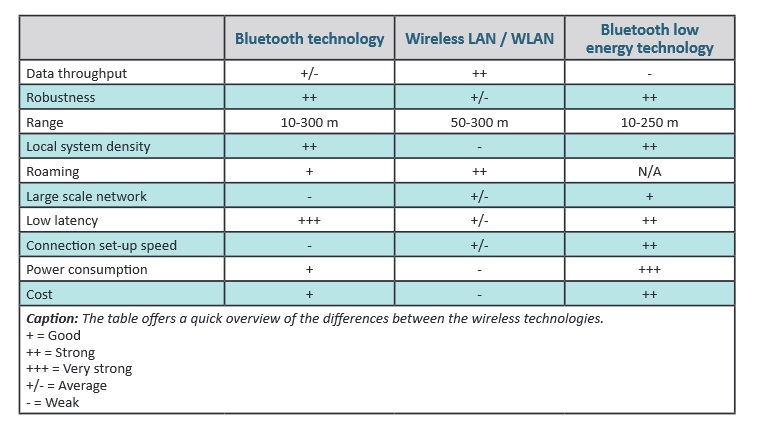

When building a machine, skid or industrial application, engineers often re-use IP addresses. Network address translation (NAT) is a methodology that enables this without introducing a duplicate IP address error into the plantwide architecture. A new white paper from Cisco and Rockwell Automation, “Deploying Network Address Translation within a Converged Plantwide Ethernet Architecture,” provides guidance and validated architecture designs to help engineers deploy NAT for one machine or skid, or for an entire cell or area zone in a plant. Wireless communication in tough, demanding applications is nothing new. Wireless has been used for more than 30 years through the use of proprietary radios. However, with the modernization of industrial networks and the emergence of different Ethernet protocols, there has been an increasing demand for standardized wireless technologies. During the last 10 years, standards like Wireless LAN (IEEE 802.11) and Bluetooth technology (IEEE 802.15.1) have become the dominating wireless technologies. In 2011, Bluetooth low energy technology also entered the scene. This whitepaper compares the wireless technologies available so you can find the solution that fits your application the best.

Wireless communication in tough, demanding applications is nothing new. Wireless has been used for more than 30 years through the use of proprietary radios. However, with the modernization of industrial networks and the emergence of different Ethernet protocols, there has been an increasing demand for standardized wireless technologies. During the last 10 years, standards like Wireless LAN (IEEE 802.11) and Bluetooth technology (IEEE 802.15.1) have become the dominating wireless technologies. In 2011, Bluetooth low energy technology also entered the scene. This whitepaper compares the wireless technologies available so you can find the solution that fits your application the best.