CEOs and experts from China’s leading companies gathered in Shanghai and Beijing to explore how smart manufacturing will deliver value to the manufacturing industry and support government initiatives including China Manufacturing 2025. Hosted by Rockwell Automation (NYSE:ROK), “The Connected Enterprise CEO Forum” was led by Rockwell Automation’s new president and CEO, Blake Moret.

CEOs and experts from China’s leading companies gathered in Shanghai and Beijing to explore how smart manufacturing will deliver value to the manufacturing industry and support government initiatives including China Manufacturing 2025. Hosted by Rockwell Automation (NYSE:ROK), “The Connected Enterprise CEO Forum” was led by Rockwell Automation’s new president and CEO, Blake Moret.

Rockwell Automation refers to The Connected Enterprise as the connection of information from the plant floor to the rest of the enterprise. This delivers unprecedented business value by bringing together people, processes and technology to achieve enhanced productivity, sustainability and economic performance. The Connected Enterprise is enabled by an integrated control and information architecture that delivers a smarter, more productive and more secure environment.

“The Connected Enterprise is a future-proof vision available today that is perfectly aligned with the Chinese government’s “China Manufacturing 2025” and “Internet Plus” initiatives, to help China transition to smart manufacturing,” said Moret.

“Connecting operations technology with information technology has become a business imperative,” added Moret. “The Connected Enterprise is how companies will realize tangible business value. For example, it will enable pharmaceutical companies to comply with stringent regulations; the consumer industry to be more flexible to changing market trends; and bring greater efficiency to heavy industry.”

China’s traditional industries, facing the problem of overcapacity, are considering moving abroad for further development. Last year, China’s Overseas Direct Investment (ODI) surpassed its Foreign Direct Investment (FDI) for the first time. It is crucial now for Chinese companies to enhance quality as well as plant productivity to compete globally. As they move to cultivate markets outside of China, The Connected Enterprise will help those companies address a number of challenges, including global differences in standards and regulations.

“Rockwell Automation is well-positioned to help Chinese companies invest globally,” said Bob Buttermore, managing director, Rockwell Automation Greater China. “Our Connected Enterprise can help Chinese companies boost global competitiveness by connecting their people, processes and assets for global optimization. Additionally, our global network covers over 80 countries and can help companies meet local manufacturing standards, access available support resources and build the infrastructure for global plant-wide optimization.”

The International Society of Automation (ISA) has announced the 2020 ISA Celebrating Excellence award recipients. The recognitions reflect and honor the outstanding efforts of ISA members in supporting and advancing the Society and the automation community. There are 14 Celebrating Excellence awardees in 2020. The Honors & Awards Committee was chaired by Brian Curtis. The ISA awards program endeavors to stimulate, enhance, encourage, acknowledge, and reward outstanding contributions to ISA and the automation profession by providing an avenue for individuals to compete for recognition within established categories.

The International Society of Automation (ISA) has announced the 2020 ISA Celebrating Excellence award recipients. The recognitions reflect and honor the outstanding efforts of ISA members in supporting and advancing the Society and the automation community. There are 14 Celebrating Excellence awardees in 2020. The Honors & Awards Committee was chaired by Brian Curtis. The ISA awards program endeavors to stimulate, enhance, encourage, acknowledge, and reward outstanding contributions to ISA and the automation profession by providing an avenue for individuals to compete for recognition within established categories.

Siemens is the first company to obtain security certification from TÜV SÜD (German inspection and certification organisation) for an automation system based on IEC 62443-4-1 and IEC 62443-3-3. In August 2016, Siemens had already become the first company to receive the TÜV SÜD security certification according to IEC 62443-4-1 for the general development process for automation and drive technology products, including industrial software, employed at seven German development locations. This has now been followed by the first product certification according to IEC 62443-4-1 and 62443-3-3.

Siemens is the first company to obtain security certification from TÜV SÜD (German inspection and certification organisation) for an automation system based on IEC 62443-4-1 and IEC 62443-3-3. In August 2016, Siemens had already become the first company to receive the TÜV SÜD security certification according to IEC 62443-4-1 for the general development process for automation and drive technology products, including industrial software, employed at seven German development locations. This has now been followed by the first product certification according to IEC 62443-4-1 and 62443-3-3. CEOs and experts from China’s leading companies gathered in Shanghai and Beijing to explore how smart manufacturing will deliver value to the manufacturing industry and support government initiatives including China Manufacturing 2025. Hosted by Rockwell Automation (NYSE:ROK), “The Connected Enterprise CEO Forum” was led by Rockwell Automation’s new president and CEO, Blake Moret.

CEOs and experts from China’s leading companies gathered in Shanghai and Beijing to explore how smart manufacturing will deliver value to the manufacturing industry and support government initiatives including China Manufacturing 2025. Hosted by Rockwell Automation (NYSE:ROK), “The Connected Enterprise CEO Forum” was led by Rockwell Automation’s new president and CEO, Blake Moret. Yokogawa Electric Corporation announces to release ProSafe®-RS R4.02.00. With this latest release of the ProSafe®-RS safety instrumented system, a number of functional safety management (FSM) related functions have been added to the Automation Design Suite (AD Suite) engineering environment for ProSafe-RS that will support our customers in ensuring safety throughout the plant lifecycle.

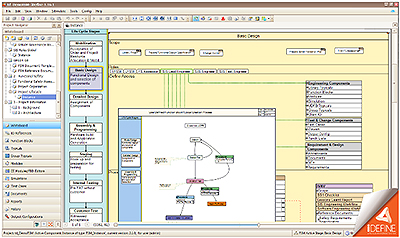

Yokogawa Electric Corporation announces to release ProSafe®-RS R4.02.00. With this latest release of the ProSafe®-RS safety instrumented system, a number of functional safety management (FSM) related functions have been added to the Automation Design Suite (AD Suite) engineering environment for ProSafe-RS that will support our customers in ensuring safety throughout the plant lifecycle. Yokogawa Electric Corporation announces that its CENTUM® VP R6 integrated production control system has received the Minister of Economy, Trade and Industry Prize. The receipt of this prize was confirmed today. This is the second time a CENTUM system has received this honor, which is the highest Machine Industry Design Award; the CENTUM-XL distributed control system won the Minister of Economy, Trade and Industry Prize in 1989.

Yokogawa Electric Corporation announces that its CENTUM® VP R6 integrated production control system has received the Minister of Economy, Trade and Industry Prize. The receipt of this prize was confirmed today. This is the second time a CENTUM system has received this honor, which is the highest Machine Industry Design Award; the CENTUM-XL distributed control system won the Minister of Economy, Trade and Industry Prize in 1989.