Rockwell Software Pavilion8 Model Predictive Control (MPC) software now delivers a more user-friendly configuration environment, step-by-step prompts, warning diagnostics and flexible work flows to simplify building, maintaining and adjusting highly complex process models.

Rockwell Software Pavilion8 Model Predictive Control (MPC) software now delivers a more user-friendly configuration environment, step-by-step prompts, warning diagnostics and flexible work flows to simplify building, maintaining and adjusting highly complex process models.

“Pavilion8 software has long been known as being among the most powerful software for solving highly challenging control problems, and it is now also among the easiest to use,” said Michael Tay, Pavilion product manager for Rockwell Automation. “The solution builder tools within the software now offer MPC configuration in a modern Windows environment, giving users a more familiar and streamlined experience. For example, users can now execute right-click mouse operations and complete copy-and-paste-type actions to develop applications in the software, helping them deploy their solutions faster and reduce training and adoption times.”

Pavilion8 MPC v5.0 software remains control system independent, but smoothly integrates with the PlantPAx process automation system from Rockwell Automation and includes four key enhancements.

Windows-based configuration and support – An improved overall user experience for expert and inexperienced users alike begins with the updated, Windows-based solution builder tools, which improve work flow by enabling users to create a customized working environment and providing access to online help. For example, problems that arise during configuration will now prompt helpful, context-sensitive warning and error messages. Users can simply click on these messages to receive detailed model-creation steps that will guide them toward a resolution. Users can also more easily modify past work to simplify model maintenance and re-use.

Multivariable run-time controller – Users will also discover new time-saving features in version 5.0. The robust run-time controller has been updated to allow users to add new predictive disturbance measures in half the time as the previous version, and easily compare differences in MPC application versions. Users now can easily sort, re-name, add, delete, compare and copy MPC variables and software supporting a flexible work flow, which can help reduce troubleshooting time. Output variables, such as powder moisture from an industrial dryer or reactor pressure in a vessel, can also be used as inputs to a nonlinear control model to help simplify deployment. Multiple developments that enhance integrating control models simplify and improve run-time performance.

Continuous controller monitoring – Users can now configure their process models with specific metrics for production, quality, energy usage and other factors. They can also continuously measure their processes according to these metrics and use historical records to track ongoing benefits. The software incorporates new data efficiencies to provide a faster and more responsive trend environment, particularly for those supporting larger and more demanding systems.

Supports modern browsers and operating systems – To make the Pavilion8 experience more consistent with other software environments and improve overall ease of use, Rockwell Automation re-designed the software’s user interface to align with current technology standards. This includes support for newer browsers like Internet Explorer 11 and operating systems, such as Windows 2012.

Pavilion8 software is the leading Rockwell Automation platform for MPC and real-time environmental management. It is also the first platform to combine empirical and first principle models into a single composite model. With proven return on investment when applied to a wide range of industries, continuous processes and equipment, Pavilion8 software uses an unrestrictive and robust configuration approach. This allows it to adapt to changing business needs and to flexibly meet simple linear to the most challenging nonlinear processes.

Air Jordan IV 4 Retro Snake Skin

The stainless steel control units of the LCS series are Ex de and Ex tb certified and feature up to 4 control functions per unit. A wide variety of operators is available, and various enclosure sizes allow the devices to fit to almost every small control application.

The stainless steel control units of the LCS series are Ex de and Ex tb certified and feature up to 4 control functions per unit. A wide variety of operators is available, and various enclosure sizes allow the devices to fit to almost every small control application.

Standard logic modules and programmable logic relay systems are a suitable solution when it comes to automating small applications with minimal effort. The devices are compact, easy to wire, and can be programmed with the Logic+ or nanoNavigator software without any special knowledge.

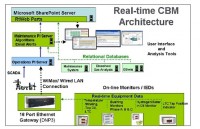

Standard logic modules and programmable logic relay systems are a suitable solution when it comes to automating small applications with minimal effort. The devices are compact, easy to wire, and can be programmed with the Logic+ or nanoNavigator software without any special knowledge. Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including:

Every company is dependent on some type of asset that keeps the business in business – be it a computer, a centrifuge, or a megawatt transformer. In a large enterprise, reducing costs related to asset maintenance, repair, and ultimate replacement is at the top of management concerns. Downtime in any network, manufacturing, or computer system ultimately results not only in high repair costs, but in customer dissatisfaction and lower potential sales. In response to these concerns, this paper presents a methodology for creating a real-time Condition-based Maintenance (CBM) solution with the OSIsoft PI System. It provides valuable guidelines for planning an enterprise system that monitors critical maintenance processes and assets. This paper provides answers to many high priority CBM questions including: Red Lion Controls, the global experts in communication, monitoring and control for industrial automation and networking, today announced that it has expanded its Graphite™ Human Machine Interface (HMI) operator panels with two new communication modules, offering support for some of today’s most popular industrial protocols. Designed for use with the Graphite HMI platform, the PROFIBUS® (GMPBDP) and DeviceNet™ (GMDN) plug-in modules provide the connectivity customers need to add powerful monitoring and control functionality to their existing operations.

Red Lion Controls, the global experts in communication, monitoring and control for industrial automation and networking, today announced that it has expanded its Graphite™ Human Machine Interface (HMI) operator panels with two new communication modules, offering support for some of today’s most popular industrial protocols. Designed for use with the Graphite HMI platform, the PROFIBUS® (GMPBDP) and DeviceNet™ (GMDN) plug-in modules provide the connectivity customers need to add powerful monitoring and control functionality to their existing operations. Rockwell Software Pavilion8 Model Predictive Control (MPC) software now delivers a more user-friendly configuration environment, step-by-step prompts, warning diagnostics and flexible work flows to simplify building, maintaining and adjusting highly complex process models.

Rockwell Software Pavilion8 Model Predictive Control (MPC) software now delivers a more user-friendly configuration environment, step-by-step prompts, warning diagnostics and flexible work flows to simplify building, maintaining and adjusting highly complex process models. Emerson Process Management has introduced the CSI 3000 Machinery Health Monitor, a compact protection system for a wide range of machinery such as pumps, compressors, centrifuges, blowers, and generators. The CSI 3000 delivers protection data in situations where a standard rack-based system simply will not fit or is not a cost-effective approach. Easy assembly and user-friendly, customizable setup means the CSI 3000 has a short path out of the box to improving availability and ensuring safety of rotating assets.

Emerson Process Management has introduced the CSI 3000 Machinery Health Monitor, a compact protection system for a wide range of machinery such as pumps, compressors, centrifuges, blowers, and generators. The CSI 3000 delivers protection data in situations where a standard rack-based system simply will not fit or is not a cost-effective approach. Easy assembly and user-friendly, customizable setup means the CSI 3000 has a short path out of the box to improving availability and ensuring safety of rotating assets. AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments.

AQUALGAE is a Spanish company specialized in integral solutions for microalgae production, including design and manufacture of photobioreactors, supply of microalgae strains and culture media. Microalgae play a key role in aquaculture, food and feed industry, and may prove to be outstanding for better biofuels, food and pharmaceuticals, and water/wastewater treatments. Yokogawa Electric Corporation announces the May 29 release of FAST/TOOLS® R10.02, the latest version of a web-based real-time operations management and visualization software package that brings revolutionary changes to real-time process information intelligence. This release is designed to significantly reduce engineering of large geographically dispersed systems, which requires both a different engineering approach and central managed deployment. The introduction of a master enterprise engineering database establishes a single engineering environment containing all common enterprise definitions and deployment data. This is easier to manage, less restrictive, and less complex than distributed databases.

Yokogawa Electric Corporation announces the May 29 release of FAST/TOOLS® R10.02, the latest version of a web-based real-time operations management and visualization software package that brings revolutionary changes to real-time process information intelligence. This release is designed to significantly reduce engineering of large geographically dispersed systems, which requires both a different engineering approach and central managed deployment. The introduction of a master enterprise engineering database establishes a single engineering environment containing all common enterprise definitions and deployment data. This is easier to manage, less restrictive, and less complex than distributed databases.