Kepware Technologies, a software development company focused on communications for automation, has announced the opening of its Tokyo, Japan office. While the company has a solid foothold in more than 100 countries through channel partners, this marks the first international location for Kepware.

Kepware Technologies, a software development company focused on communications for automation, has announced the opening of its Tokyo, Japan office. While the company has a solid foothold in more than 100 countries through channel partners, this marks the first international location for Kepware.

The office is located at 8F Pacific Century Place in the Chiyoda district of Tokyo, and led by Liem Le, International Sales Director, Asia Pacific, Middle East, and Africa (AP MEA), Kepware. The Tokyo office will focus on business development opportunities and building partner relationships.

"We are excited to announce the launch of our Tokyo office," said Brett Austin, President, Kepware. "Expanding Kepware’s presence in global markets and delivering regionalized software solutions are major initiatives over the next few years. With our Japan location, we will be able to interact more closely with both our customers and partners in the area, strengthening those relationships and supporting future growth."

Kepware’s Preferred Distributor in Japan, Kanto L-Engineering Co. (KLEC), will join the company during a press conference on July 15th at the TKP Tokyo-eki Yaesu Conference Center to discuss details about the new location. KLEC promotes, distributes, and provides support for all software solutions across Kepware's product portfolio.

"Kepware’s flagship product, KEPServerEX, leverages OPC and IT-centric communication protocols, making it the world’s leading communications platform for the industrial automation industry," said Choulho Kim, President, KLEC. "We are proud to partner with Kepware and provide distribution to the Japanese market. It is a great honor for us to be able to contribute to the expansion of Kepware’s global business, and we look forward to working closely with the Tokyo office."

Nike

Following an accidental fire at the IOCL Jaipur Terminal, an extensive review of safety measures recommended by the MB Lal Committee has resulted in the introduction of failsafe actuators for critical tank farm applications. These valves, known as ROSOV (Remote Operated Shut-off Valves), now provide tank overfill protection at the majority of storage facilities owned by the Indian oil industry.

Following an accidental fire at the IOCL Jaipur Terminal, an extensive review of safety measures recommended by the MB Lal Committee has resulted in the introduction of failsafe actuators for critical tank farm applications. These valves, known as ROSOV (Remote Operated Shut-off Valves), now provide tank overfill protection at the majority of storage facilities owned by the Indian oil industry. Utilizing and maintaining level and flow control instrumentation requires knowledge of a wide range of technical information. Having a quick and comprehensive reference point for this information can help keep equipment running smoothly and efficiently. With that in mind, Magnetrol® has produced a free field instrumentation technical handbook featuring a compendium of physical constants, tables and other essential information. The handbook was created by MAGNETROL to cover specific reference points that are commonly used in process applications.

Utilizing and maintaining level and flow control instrumentation requires knowledge of a wide range of technical information. Having a quick and comprehensive reference point for this information can help keep equipment running smoothly and efficiently. With that in mind, Magnetrol® has produced a free field instrumentation technical handbook featuring a compendium of physical constants, tables and other essential information. The handbook was created by MAGNETROL to cover specific reference points that are commonly used in process applications. Matrikon recently announced the major release of its popular OPC UA Proxy application. The OPC UA Proxy enables software applications based on classic OPC client connectivity to seamlessly communicate with next generation OPC UA-based devices and applications. With a simplified user interface, improved workflow and enhanced performance – the new Matrikon OPC UA Proxy is an easy, convenient way for people to combine their existing classic OPC infrastructures with the growing number of next-generation OPC UA-based products.

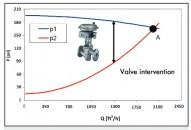

Matrikon recently announced the major release of its popular OPC UA Proxy application. The OPC UA Proxy enables software applications based on classic OPC client connectivity to seamlessly communicate with next generation OPC UA-based devices and applications. With a simplified user interface, improved workflow and enhanced performance – the new Matrikon OPC UA Proxy is an easy, convenient way for people to combine their existing classic OPC infrastructures with the growing number of next-generation OPC UA-based products. Article by Samson Valves: The discussions revolving around the scarcity of fossil fuels and increasing energy prices have refocused on the most effective action in the long term, i.e., reducing energy consumption. The right process automation technology can contribute to achieving considerable energy savings. Status monitoring and status conservation can be of help when optimizing the technical infrastructure by preventing additional energy consumption due to plant failures, the resulting start-up and shutdown procedures, as well as the production of non-conforming products. Three major areas can also be identified when optimizing the production process—process sizing, process monitoring, and process control. This article deals with the control valve as a final control element that can help minimize energy consumption when it is accurately tuned to its assigned task. In addition, we will look at state-of-the-art asset management concepts based on smart positioners, which facilitate energy monitoring and indicate possible savings potential thanks to optimized operating modes.

Article by Samson Valves: The discussions revolving around the scarcity of fossil fuels and increasing energy prices have refocused on the most effective action in the long term, i.e., reducing energy consumption. The right process automation technology can contribute to achieving considerable energy savings. Status monitoring and status conservation can be of help when optimizing the technical infrastructure by preventing additional energy consumption due to plant failures, the resulting start-up and shutdown procedures, as well as the production of non-conforming products. Three major areas can also be identified when optimizing the production process—process sizing, process monitoring, and process control. This article deals with the control valve as a final control element that can help minimize energy consumption when it is accurately tuned to its assigned task. In addition, we will look at state-of-the-art asset management concepts based on smart positioners, which facilitate energy monitoring and indicate possible savings potential thanks to optimized operating modes. Yokogawa Solution Service Corporation, a subsidiary of Yokogawa Electric Corporation that is responsible for the company's control business in Japan, announces that a community energy management system (CEMS) that it has built and delivered to the F-Grid Ohira, Miyagi Limited Liability Partnership (LLP)* is now fully operational. The LLP is headed by Toyota Motor Corporation. Over a two-year period, this system was developed by the LLP, built by Yokogawa, and field tested. Funding for the testing of this system, which was developed as part of a smart community project undertaken by the LLP was provided by the Japanese government.

Yokogawa Solution Service Corporation, a subsidiary of Yokogawa Electric Corporation that is responsible for the company's control business in Japan, announces that a community energy management system (CEMS) that it has built and delivered to the F-Grid Ohira, Miyagi Limited Liability Partnership (LLP)* is now fully operational. The LLP is headed by Toyota Motor Corporation. Over a two-year period, this system was developed by the LLP, built by Yokogawa, and field tested. Funding for the testing of this system, which was developed as part of a smart community project undertaken by the LLP was provided by the Japanese government. OSIsoft, a global leader in operational intelligence, announced a major enhancement to its flagship product, the PI Server, that will allow predictive data to be stored natively and exposed throughout the PI System. The PI System is now able to capture, analyze and share predicted data from 3rd party advanced analytics and machine learning tools throughout the entire organization. This capability enables people to see predictions in real-time, take action to prevent events before they happen and improve operations performance based on insights into the future.

OSIsoft, a global leader in operational intelligence, announced a major enhancement to its flagship product, the PI Server, that will allow predictive data to be stored natively and exposed throughout the PI System. The PI System is now able to capture, analyze and share predicted data from 3rd party advanced analytics and machine learning tools throughout the entire organization. This capability enables people to see predictions in real-time, take action to prevent events before they happen and improve operations performance based on insights into the future. Manufacturers taking advantage of advanced technology to build a more Connected Enterprise increasingly require proven solutions and industry partners. These companies recently gained nine additional trusted resources in the Rockwell Automation PartnerNetwork program to help optimize production and maximize automation and technology investments.

Manufacturers taking advantage of advanced technology to build a more Connected Enterprise increasingly require proven solutions and industry partners. These companies recently gained nine additional trusted resources in the Rockwell Automation PartnerNetwork program to help optimize production and maximize automation and technology investments. Emerson Process Management’s Micro Motion Coriolis and Rosemount 8800 Vortex Flowmeters have been certified to the ASME B31.1 Power Piping design standards, in addition to the existing B31.3 Process Piping design standard.

Emerson Process Management’s Micro Motion Coriolis and Rosemount 8800 Vortex Flowmeters have been certified to the ASME B31.1 Power Piping design standards, in addition to the existing B31.3 Process Piping design standard.