As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

The Industrial IoT is elevating the need for highly flexible, secure connectivity between things, machines, work flows, databases and people, enabling new models of policy-based plant-floor access. Through these new connections, machine data on the plant floor can be analyzed and applied to determine optimal operation and supply-chain work flows for improved efficiencies and cost savings. A securely connected environment also enables organizations to mitigate risk with policy compliance, and protects intellectual property with secure sharing between global stakeholders.

Core to the new validated architectures is a focus on enabling OT and IT professionals to utilize security policies and procedures by forming multiple layers of defense. A defense-in-depth approach helps manufacturers by establishing processes and policies that identify and contain evolving threats in industrial automation and control systems. The new CPwE architectures leverage open industry standards, such as IEC 62443, and provide recommendations for more securely sharing data across an industrial demilitarized zone, as well as enforcing policies that control access to the plantwide wired or wireless network.

“The key to industrial network security is in how you design and implement your infrastructure and holistically address security for internal and external threats,” said Lee Lane, business director, Rockwell Automation. “The new guidance considers security factors for the industrial zone of the CPwE architectures, leveraging the combined experience of Rockwell Automation and Cisco.”

Rockwell Automation and Cisco have created resources to help manufacturers efficiently deploy security solutions. Each new guide is accompanied by a white paper summarizing the key design principles, as follows:

The Industrial Demilitarized Zone Design and Implementation Guide and white paper provide guidance to users on securely sharing data from the plant floor through the enterprise.

The Identity Services Design and Implementation Guide and white paper introduce an approach to security policy enforcement that tightly controls access by anyone inside the plant, whether they’re trying to connect via wired or wireless access.

“Security can’t be an afterthought in today’s plant environment. As we connect more devices and create more efficient ways of operating, we also create certain vulnerabilities,” said Bryan Tantzen, senior director, Cisco. “Cisco and Rockwell Automation have been teaming for nearly a decade on joint solutions, serving as the standards-based resource for security in industrial environments. These new architectures and guides build on our collaboration by helping organizations recognize and proactively address today’s security concerns.”

Companies can now take advantage of industry-leading solutions from Rockwell Automation and Cisco to address security from a holistic perspective. Together, the two companies provide a common, scalable architecture for ruggedized industrial Ethernet and enterprise networks, along with unique services, such as security assessments and managed security, to help manufacturers define and meet performance metrics and scale in-house resources.

Femme

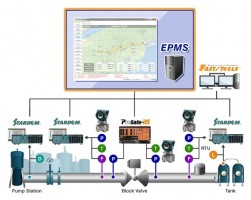

Yokogawa Electric Corporation announces the June 30 release of the Enterprise Pipeline Management Solution (EPMS), a modular software suite that is the product of our over 20 years of practical experience in implementing pipeline management solutions across the globe.

Yokogawa Electric Corporation announces the June 30 release of the Enterprise Pipeline Management Solution (EPMS), a modular software suite that is the product of our over 20 years of practical experience in implementing pipeline management solutions across the globe.

Power management company Eaton has recently announced the release of the Power Xpert® gateway (PXG) 900, an electrical system communications device designed to deliver easy, remote access to power system parameters and alarms through a Web browser. Engineered to enhance energy performance in commercial, institutional and industrial facilities, the compact solution allows for access to real-time and historical energy and power data from electrical equipment. Facility and energy management personnel can use this in-depth data to simplify decisions targeting enhanced electrical reliability, efficiency and safety.

Power management company Eaton has recently announced the release of the Power Xpert® gateway (PXG) 900, an electrical system communications device designed to deliver easy, remote access to power system parameters and alarms through a Web browser. Engineered to enhance energy performance in commercial, institutional and industrial facilities, the compact solution allows for access to real-time and historical energy and power data from electrical equipment. Facility and energy management personnel can use this in-depth data to simplify decisions targeting enhanced electrical reliability, efficiency and safety. As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise. Technip, in a consortium with Petrovietnam Technical Services Corporation (PTSC), has been awarded a engineering, procurement, construction and commissioning contract by PetroVietnam Fertilizer and Chemicals Corporation (PVFCCo). The project covers the revamping of the ammonia plant at the existing Phu My Fertilizer Complex, located in southern Ba Ria-Vung Tau Province, Vietnam.

Technip, in a consortium with Petrovietnam Technical Services Corporation (PTSC), has been awarded a engineering, procurement, construction and commissioning contract by PetroVietnam Fertilizer and Chemicals Corporation (PVFCCo). The project covers the revamping of the ammonia plant at the existing Phu My Fertilizer Complex, located in southern Ba Ria-Vung Tau Province, Vietnam. ABB, the leading power and automation technology group, has won an order from offshore services provider Bumi Armada Berhad to supply electrification and automation systems for a floating production, storage and offloading (FPSO) vessel for a recently discovered oilfield off the coast of Angola. The order was booked in the first quarter.

ABB, the leading power and automation technology group, has won an order from offshore services provider Bumi Armada Berhad to supply electrification and automation systems for a floating production, storage and offloading (FPSO) vessel for a recently discovered oilfield off the coast of Angola. The order was booked in the first quarter. The new ADAM-3600 is an intelligent RTU designed to work in the hardest environments with minimal physical contact from engineers once installed. The ADAM-3600 utilizes Advantech’s TagLink Technology, a modular wireless expansion system and wide operating temperatures.

The new ADAM-3600 is an intelligent RTU designed to work in the hardest environments with minimal physical contact from engineers once installed. The ADAM-3600 utilizes Advantech’s TagLink Technology, a modular wireless expansion system and wide operating temperatures. In a recent move, Emerson announced it has acquired Energy Solutions International Holdings, Inc. (ESI), a leading global supplier of decision support software and services that enhance operational efficiency, commercial profitability and safety across the oil and gas pipeline, storage, marketing and distribution functions.

In a recent move, Emerson announced it has acquired Energy Solutions International Holdings, Inc. (ESI), a leading global supplier of decision support software and services that enhance operational efficiency, commercial profitability and safety across the oil and gas pipeline, storage, marketing and distribution functions. National Instruments, the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, announced today the NI PXIe-8880 controller, which is based on the Intel® Xeon® processor, and the NI PXIe-1085 chassis, which is the industry’s first chassis that uses PCI Express Gen 3 technology. The combination of the eight-core, server-class Intel® Xeon® processor E5-2618L v3 and full system bandwidth of 24 GB/s delivers breakthrough performance for computationally intensive and highly parallel applications such as wireless test, semiconductor test and 5G prototyping. Customers can take advantage of the flexibility of the PXI platform to replace previous generation controllers with the NI PXIe-8880 and see up to double the performance in their test and measurement applications.

National Instruments, the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, announced today the NI PXIe-8880 controller, which is based on the Intel® Xeon® processor, and the NI PXIe-1085 chassis, which is the industry’s first chassis that uses PCI Express Gen 3 technology. The combination of the eight-core, server-class Intel® Xeon® processor E5-2618L v3 and full system bandwidth of 24 GB/s delivers breakthrough performance for computationally intensive and highly parallel applications such as wireless test, semiconductor test and 5G prototyping. Customers can take advantage of the flexibility of the PXI platform to replace previous generation controllers with the NI PXIe-8880 and see up to double the performance in their test and measurement applications. The latest addition to the market-leading range of gearboxes manufactured by Rotork Gears is a rugged, industrial grade product designed for use with motorised quarter-turn valves and dampers.

The latest addition to the market-leading range of gearboxes manufactured by Rotork Gears is a rugged, industrial grade product designed for use with motorised quarter-turn valves and dampers.