ABB, the leading power and automation technology group, has opened a new local service office near Lake Charles, Louisiana. The office will provide services and support for ABB’s automation and power portfolio including control systems (System 800xA, Symphony Plus, and heritage control systems), instrumentation, analytical products, low voltage drives, and power systems and products.

ABB, the leading power and automation technology group, has opened a new local service office near Lake Charles, Louisiana. The office will provide services and support for ABB’s automation and power portfolio including control systems (System 800xA, Symphony Plus, and heritage control systems), instrumentation, analytical products, low voltage drives, and power systems and products.

The new office will be staffed with engineering, support and training personnel and will offer scheduled in-center training, as well as customized training courses. It is scheduled to open in mid-April 2015. ABB will hold an open house for its customers on April 15, 2015, from 8:30 am to 6:30 pm. The address is 2492 South Cities Service Highway, Calcasieu Parish, Sulphur, Louisiana 70663.

The open house will feature a wide variety of ABB automation and power equipment including wireless communications, measurement and analytical products (instrumentation, level and process analytics), gas insulated switchgear, protection relays and other control and power products.

ABB has established local resources to serve its industry customers in the Gulf region, which is a major hub for energy, oil, gas, chemical and petrochemical industries in the United States, and has recently announced several new investments in the area.

“We are expanding our footprint in the Gulf region to better serve our customers here, with local service and support resources that work with our global experts,” said Kevin Kosisko, Americas Region Division Manager, Process Automation for ABB. “This office nicely complements our recent expansions in this area, including the Automation and Power Center in Houston and new level measurement factory currently under construction in Baton Rouge.”

Last month, ABB held a ground-breaking ceremony for its new 75,000-sq-ft level measurement factory in Baton Rouge, Louisiana, and announced that it is developing a new Automation and Power Center in Houston that will showcase ABB’s full offering to help utility, industry and infrastructure companies increase their productivity and energy efficiency while maintaining the highest level safety and reliability.

ABB (www.abb.com) is a global leader in power and automation technologies that enable utility and industry customers to improve performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 140,000 people. The company has invested heavily in North America over the past five years, with acquisitions totaling nearly $10 billion. ABB employs around 30,000 people throughout the region.

New Balance Running Shoes

THE SERIES IWP PRESSURE TRANSMITTER provides an exceptional value solution to pressure measurement in industrial conditions requiring high-performance, stability and long service life. The transmitter delivers a 4 to 20 mA signal in response to the pressure being measured against its stainless steel diaphragm for process system monitoring and feedback-control. Additionally the 4-digit LED display simultaneously allows for easy field inspection of pressure in psi units to support monitoring process parameters. Made of cast aluminum and IP65 rated or industrial conduit entry enclosure ensures the high quality sensor circuitry is able to maintain precise operation under dirty and wet conditions, making the Series IWP an ideal choice for petroleum, chemical and metallurgical industry applications.

THE SERIES IWP PRESSURE TRANSMITTER provides an exceptional value solution to pressure measurement in industrial conditions requiring high-performance, stability and long service life. The transmitter delivers a 4 to 20 mA signal in response to the pressure being measured against its stainless steel diaphragm for process system monitoring and feedback-control. Additionally the 4-digit LED display simultaneously allows for easy field inspection of pressure in psi units to support monitoring process parameters. Made of cast aluminum and IP65 rated or industrial conduit entry enclosure ensures the high quality sensor circuitry is able to maintain precise operation under dirty and wet conditions, making the Series IWP an ideal choice for petroleum, chemical and metallurgical industry applications.

Technip and its consortium partner China Offshore Oil Engineering Company (COOEC) have been awarded a front end engineering design (FEED) contract by China National Offshore Oil Corporation Limited (CNOOC Ltd.) for two tension leg platforms (TLPs) for the Liuhua joint development project located in the South China Sea.

Technip and its consortium partner China Offshore Oil Engineering Company (COOEC) have been awarded a front end engineering design (FEED) contract by China National Offshore Oil Corporation Limited (CNOOC Ltd.) for two tension leg platforms (TLPs) for the Liuhua joint development project located in the South China Sea. The Thermatel® Model TA2 thermal mass flow transmitter, based on thermal dispersion technology, provides reliable mass measurement for air and gas flow applications. The powerful, yet easy-to-use, electronics are contained in a compact explosion-proof enclosure. The TA2 is available with both insertion probes, as well as flow body design for smaller pipe sizes. The TA2 offers excellent performance at an exceptional value. The TA2 offers the user the ability to verify calibration in the field, reducing the need for periodic recalibration.

The Thermatel® Model TA2 thermal mass flow transmitter, based on thermal dispersion technology, provides reliable mass measurement for air and gas flow applications. The powerful, yet easy-to-use, electronics are contained in a compact explosion-proof enclosure. The TA2 is available with both insertion probes, as well as flow body design for smaller pipe sizes. The TA2 offers excellent performance at an exceptional value. The TA2 offers the user the ability to verify calibration in the field, reducing the need for periodic recalibration. exida, a global supplier of functional safety products, services and certifications has released LOPAxTM, a Layer of Protection Analysis (LOPA) software that supports process safety management activities.

exida, a global supplier of functional safety products, services and certifications has released LOPAxTM, a Layer of Protection Analysis (LOPA) software that supports process safety management activities. Manufacturers in both the process and discrete manufacturing industries should consider condition monitoring (CM) for critical assets to improve the effectiveness of their maintenance resources. Typical benefits include improved uptime, asset longevity, cost control, yield/quality and safety. A study by a major petroleum company showed that, compared to calendar-based preventive maintenance, predictive reduces maintenance costs by 50 percent. This paper discusses the advantages of packaged predictive maintenance (PdM) applications to leverage existing process and smart device data.

Manufacturers in both the process and discrete manufacturing industries should consider condition monitoring (CM) for critical assets to improve the effectiveness of their maintenance resources. Typical benefits include improved uptime, asset longevity, cost control, yield/quality and safety. A study by a major petroleum company showed that, compared to calendar-based preventive maintenance, predictive reduces maintenance costs by 50 percent. This paper discusses the advantages of packaged predictive maintenance (PdM) applications to leverage existing process and smart device data.  ABB, the leading power and automation technology group, has won an order from PT Fajar Surya Wisesa Tbk (Fajar Paper), a leading packaging paper manufacturer in Indonesia. The contract was booked end of 2014. ABB will provide the automation system for paper machine 3 (PM3), one of the current five paper machines at Fajar Paper responsible for a combined production of around 1.2 million tons of packaging paper per year, including Coated Duplex Board, Kraft Liner Board and Corrugated Medium Paper.

ABB, the leading power and automation technology group, has won an order from PT Fajar Surya Wisesa Tbk (Fajar Paper), a leading packaging paper manufacturer in Indonesia. The contract was booked end of 2014. ABB will provide the automation system for paper machine 3 (PM3), one of the current five paper machines at Fajar Paper responsible for a combined production of around 1.2 million tons of packaging paper per year, including Coated Duplex Board, Kraft Liner Board and Corrugated Medium Paper. The accurate measurement of liquid levels in power plant operations is key to efficient operation. Although water is a liquid that can be easily measured by numerous measurement technologies, detection in applications like feedwater heaters, for example, takes on a range of complexity that stresses even the most robust devices.

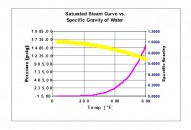

The accurate measurement of liquid levels in power plant operations is key to efficient operation. Although water is a liquid that can be easily measured by numerous measurement technologies, detection in applications like feedwater heaters, for example, takes on a range of complexity that stresses even the most robust devices. The ST98 Flow Meter’s thermal mass flow sensor design provides direct mass flow measurement without the need for additional temperature or pressure sensors or density calculating devices, as well as the plant real estate and technician time needed to install these extra devices at their additional cost. Its insertion style configuration makes the ST98 meter simple to install in existing piping without cutting the pipe or welding, offering minimal interruption to plant operations. The flexible and dependable ST98 flow meter is suitable for service in plant natural gas and numerous other process gases, hydrocarbon mixed or dirty gases, biogases including methane, and plant compressed air and HVAC systems.

The ST98 Flow Meter’s thermal mass flow sensor design provides direct mass flow measurement without the need for additional temperature or pressure sensors or density calculating devices, as well as the plant real estate and technician time needed to install these extra devices at their additional cost. Its insertion style configuration makes the ST98 meter simple to install in existing piping without cutting the pipe or welding, offering minimal interruption to plant operations. The flexible and dependable ST98 flow meter is suitable for service in plant natural gas and numerous other process gases, hydrocarbon mixed or dirty gases, biogases including methane, and plant compressed air and HVAC systems.