More and more applications in the industrial and hazardous area building automation sector require high performance and easy to use control systems. The local control of variable air volume (VAV) and constant air volume (CAV) systems as well as pressure, temperature and humidity eliminates the need for connection to remote controllers.

More and more applications in the industrial and hazardous area building automation sector require high performance and easy to use control systems. The local control of variable air volume (VAV) and constant air volume (CAV) systems as well as pressure, temperature and humidity eliminates the need for connection to remote controllers.

Air volume control is the key to delivering cost effective and environmentally friendly ventilation in modern buildings and industrial facilities. By locally controlling the movement of air dampers, the flow of air in to a room can be optimally controlled for the times when the room is occupied or not in use.

Rotork Schischek provides the solution with the introduction of ExReg-V (hazardous area) and InReg-V (safe area) control units, designed to ensure smooth operation when controlling HVAC systems by minimising the number of separate components required. A variant of the ExReg-V controller, the ExCos-V sensor, allows for the measurement and monitoring of air flow (volume) or speed (velocity) in industrial and safety critical ventilation systems.

In a related scenario, the local control and actuation of 2 and 3-way water mixing and diverting valves allows for the regulation of temperature and humidity in buildings and environments where the maintenance of strict limits is a prerequisite. Examples of such applications include the manufacture and storage of temperature and humidity sensitive materials which, if exposed to levels outside those specified, could cause a threat to life, health and assets. Here, the ExReg-D or InReg-D controllers used with the ExPro-CT and ExPro-CF sensor range provides the solution.

Developed from the successful ExCos and ExBin sensor series used extensively in hazardous area locations including ATEX zones 1,2,21 & 22, the new ExReg control units feature a compact design which incorporates an internal proportional-integral-derivative (PID) control structure. The parameterisation process is easy to use and automatically achieved for standard applications. The system provides support, especially during the start-up process, with many predefined settings and damper characteristics.

Features retained from the ExCos and ExBin series include the elimination of intrinsically safe wiring, digital adjustment, actual value indication and LED status display. Designed for electrical and mechanical compatibility with market standards, the ExReg is suitable for 24Vac or dc supplies and environmentally protected to IP66.

sneakers

You never have to worry again about losing critical temperature measurements because of a sensor failure thanks to the new THZ3 and TDZ3 Smart HART® Dual Input Temperature Transmitters from Moore Industries. With two inputs, users can select one as a backup in case there is a failure with the primary sensor. If there is a problem with the main sensor, the transmitter automatically switches to the backup sensor.

You never have to worry again about losing critical temperature measurements because of a sensor failure thanks to the new THZ3 and TDZ3 Smart HART® Dual Input Temperature Transmitters from Moore Industries. With two inputs, users can select one as a backup in case there is a failure with the primary sensor. If there is a problem with the main sensor, the transmitter automatically switches to the backup sensor. Cobham Wireless, formerly the Wireless Test Business of Aeroflex, and NI (Nasdaq: NATI), the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced a worldwide partnership to service applications in cellular and connectivity with solutions based on PXI technology.

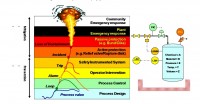

Cobham Wireless, formerly the Wireless Test Business of Aeroflex, and NI (Nasdaq: NATI), the provider of platform-based systems that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced a worldwide partnership to service applications in cellular and connectivity with solutions based on PXI technology. White Paper by Exida: Some of the significant process industries incidents occurred by overflowing vessels, including BP Texas City and Buncefield. In many overflow incidents, alarms were designed to signal the need for operator intervention. These alarms may have been identified as safeguards or layers of protection, but they did not succeed in preventing the incident. This paper reviews several overflow incidents to consider the alarm management and human factors elements of the failures.

White Paper by Exida: Some of the significant process industries incidents occurred by overflowing vessels, including BP Texas City and Buncefield. In many overflow incidents, alarms were designed to signal the need for operator intervention. These alarms may have been identified as safeguards or layers of protection, but they did not succeed in preventing the incident. This paper reviews several overflow incidents to consider the alarm management and human factors elements of the failures. Matrikon has announced that Version 2.0 of the Matrikon OPC UA Embedded Software Development Kit (SDK) has been certified by the OPC Foundation’s Independent test labs to be compliant with the Embedded OPC Server profile.

Matrikon has announced that Version 2.0 of the Matrikon OPC UA Embedded Software Development Kit (SDK) has been certified by the OPC Foundation’s Independent test labs to be compliant with the Embedded OPC Server profile. State-run Abu Dhabi National Oil Company (ADNOC) has signed a technical agreement with US-based Occidental Petroleum to develop the al-Hail and Ghasha oilfields. "Under the terms of the new agreement, ADNOC and Oxy will cooperate in carrying out a number of activities that reach up to $500 million in investment," ADNOC said in a statement.

State-run Abu Dhabi National Oil Company (ADNOC) has signed a technical agreement with US-based Occidental Petroleum to develop the al-Hail and Ghasha oilfields. "Under the terms of the new agreement, ADNOC and Oxy will cooperate in carrying out a number of activities that reach up to $500 million in investment," ADNOC said in a statement. The TR-71wf temperature data logger is a two channel model with an external thermistor sensor and a measuring range of -40 to 110°C. In addition to the standard features such as battery operation and USB communication (through optional cable, sold separately), the TR-71wf supports communication with mobile devices. By using T&D's WebStorage Service, users can access stored data anytime from the cloud.

The TR-71wf temperature data logger is a two channel model with an external thermistor sensor and a measuring range of -40 to 110°C. In addition to the standard features such as battery operation and USB communication (through optional cable, sold separately), the TR-71wf supports communication with mobile devices. By using T&D's WebStorage Service, users can access stored data anytime from the cloud. The new series of integrated hardware, software and services from Schneider Electric combine world-class hardware, best-of-breed Wonderware software with the tight integration to the Wonderware By Schneider Electric portfolio, extensive plant communications capabilities and award-winning support services. This new series is a complete solution, from small footprint machine level HMI software (InTouch Machine Edition) to whole plant supervisory visualization solution with InTouch and InTouch for System Platform, on one simplified order that enables a consistent plant intelligence software solution across a broad spectrum of industrial applications.

The new series of integrated hardware, software and services from Schneider Electric combine world-class hardware, best-of-breed Wonderware software with the tight integration to the Wonderware By Schneider Electric portfolio, extensive plant communications capabilities and award-winning support services. This new series is a complete solution, from small footprint machine level HMI software (InTouch Machine Edition) to whole plant supervisory visualization solution with InTouch and InTouch for System Platform, on one simplified order that enables a consistent plant intelligence software solution across a broad spectrum of industrial applications. White paper by Invensys: The end users of modern industrial systems are constantly searching for methods of improving the availability and maximizing the efficiency of those systems without compromising the quality of their offerings or safety of their operations teams. One of the areas where improvements can have significant impacts in this pursuit is quite literally star ing them in the face; the human machine interface used to control and operate these systems. By implementing improvements in the mechanisms used to control and operate industrial systems, operations teams can significantly improve both the business value and the safety of their industrial systems.

White paper by Invensys: The end users of modern industrial systems are constantly searching for methods of improving the availability and maximizing the efficiency of those systems without compromising the quality of their offerings or safety of their operations teams. One of the areas where improvements can have significant impacts in this pursuit is quite literally star ing them in the face; the human machine interface used to control and operate these systems. By implementing improvements in the mechanisms used to control and operate industrial systems, operations teams can significantly improve both the business value and the safety of their industrial systems.