Foster Wheeler AG (“Foster Wheeler” or the “Company”) today announced that it has entered into a definitive agreement with AMEC plc (“AMEC”) pursuant to which AMEC will make an offer to acquire all the issued and to be issued share capital of the Company. Under the terms of the offer, AMEC will offer to exchange for each outstanding share of Foster Wheeler common stock transaction consideration consisting of 0.8998 shares of AMEC stock and $16.00 in cash.

Foster Wheeler AG (“Foster Wheeler” or the “Company”) today announced that it has entered into a definitive agreement with AMEC plc (“AMEC”) pursuant to which AMEC will make an offer to acquire all the issued and to be issued share capital of the Company. Under the terms of the offer, AMEC will offer to exchange for each outstanding share of Foster Wheeler common stock transaction consideration consisting of 0.8998 shares of AMEC stock and $16.00 in cash.

Separately, Foster Wheeler expects to pay a one-time dividend of $0.40 per share prior to, and not conditional on, the closing of the offer. The Company expects that there will be no Swiss withholding taxes on the dividend.

Today’s announcement follows the January 13, 2014 announcement of a provisional agreement between the parties.

Based on AMEC's stock price of £10.92 per share (the close of trading on February 12, 2014) and an exchange rate of £/$1.658, the proposed transaction would value each Foster Wheeler share at approximately $32.69 and the fully diluted share capital of Foster Wheeler at approximately $3.3 billion (taking into account the proposed $0.40 dividend by the Company). This represents a premium of approximately 13.8% to $28.73, the Company's closing stock price on November 26, 2013, the trading day prior to initial public reports about a potential business combination involving the Company and AMEC, and a premium of approximately 20.4% to the 3-month volume weighted average price (measured for the three-months ending on November 26, 2013) of approximately $27.15.

Kent Masters, President and Chief Executive Officer of Foster Wheeler, said, “Both companies have strategies that are highly focused on growth, and our combination will help deliver on Foster Wheeler’s key strategic objectives: establishing material positions in upstream and minerals and metals, building positions in growth geographies and extending our services offering.” Specifically, the combination is expected to result in a company with:

Complementary and more competitive market positions in offshore and onshore upstream oil and gas, gas monetization, refining and chemicals, minerals and metals, power and clean energy, environment & infrastructure and pharmaceuticals

An expanded, geographically diverse global presence, with offices and projects in more than 50 countries

A material increase in capacity, with a total headcount of more than 40,000 employees

A strong financial profile, with annual pro forma revenues of approximately $10 billion and backlog of approximately $10 billion

Footwear

Yokogawa Electric Corporation announces that its subsidiary, Yokogawa Electric Korea, has received an order from Hyundai Engineering & Construction, a major engineering company in South Korea, to supply a control system for a combined cycle power plant*1 that it is building for UTE*2 in Punta del Tigre. This is the first combined cycle power plant in Uruguay and the order is Yokogawa's first for a power plant in this country.

Yokogawa Electric Corporation announces that its subsidiary, Yokogawa Electric Korea, has received an order from Hyundai Engineering & Construction, a major engineering company in South Korea, to supply a control system for a combined cycle power plant*1 that it is building for UTE*2 in Punta del Tigre. This is the first combined cycle power plant in Uruguay and the order is Yokogawa's first for a power plant in this country. There will be 304 students from 38 countries and 33 U.S. states and territories that will attend the Honeywell Leadership Challenge Academy (HLCA) this year. The unique leadership opportunity will run from February 21 to March 7, 2014 at the U.S. Space & Rocket Center in Huntsville, Ala.

There will be 304 students from 38 countries and 33 U.S. states and territories that will attend the Honeywell Leadership Challenge Academy (HLCA) this year. The unique leadership opportunity will run from February 21 to March 7, 2014 at the U.S. Space & Rocket Center in Huntsville, Ala. Yokogawa has announced the new CENTUM VP and how it was going to take VigilantPlant, our vision for the ideal plant in industrial automation, to the next level. It exceeds the capabilities of conventional production systems and will become the platform based on which we will provide our customers with solutions and services that maintain operational excellence over the entire plant lifecycle. Innovations are available with it.

Yokogawa has announced the new CENTUM VP and how it was going to take VigilantPlant, our vision for the ideal plant in industrial automation, to the next level. It exceeds the capabilities of conventional production systems and will become the platform based on which we will provide our customers with solutions and services that maintain operational excellence over the entire plant lifecycle. Innovations are available with it.

The International Society of Automation (ISA) has announced that, beginning in March, it will conduct four highly intensive technical training events—comprised of world-class technician, automation engineering and safety courses—in Denver, Colorado; Houston, Texas; and Carson, California during 2014.

The International Society of Automation (ISA) has announced that, beginning in March, it will conduct four highly intensive technical training events—comprised of world-class technician, automation engineering and safety courses—in Denver, Colorado; Houston, Texas; and Carson, California during 2014. Invensys has unveiled a new version of its SimSci® advanced process control software. To be released this spring, SimSci APC 2014 will enable customers to shorten their plant testing and commissioning schedules, as well as improve plant operations and personnel performance.

Invensys has unveiled a new version of its SimSci® advanced process control software. To be released this spring, SimSci APC 2014 will enable customers to shorten their plant testing and commissioning schedules, as well as improve plant operations and personnel performance. ase throughput and reduce energy usage," said Tom Kinney, vice president of Invensys' optimization business. "The software was developed with the end user in mind, and it includes several well-thought-out features that help achieve better and more sustainable control of the process. A built-in auto-discovery wizard captures the specific syntax of any DCS for even faster buildup of tag connections; its automated testing feature means faster, more flexible configuration; it's tablet ready; new click-and-drag functionality allows users to select the best models from many scenarios; and customizable user-defined functions improve how users can cope with changing process conditions. The end result is that SimSci APC 2014 provides a better, friendlier and more flexible user experience than traditional APC applications, making operators and engineers far more effective and productive."

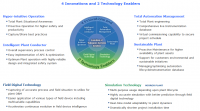

ase throughput and reduce energy usage," said Tom Kinney, vice president of Invensys' optimization business. "The software was developed with the end user in mind, and it includes several well-thought-out features that help achieve better and more sustainable control of the process. A built-in auto-discovery wizard captures the specific syntax of any DCS for even faster buildup of tag connections; its automated testing feature means faster, more flexible configuration; it's tablet ready; new click-and-drag functionality allows users to select the best models from many scenarios; and customizable user-defined functions improve how users can cope with changing process conditions. The end result is that SimSci APC 2014 provides a better, friendlier and more flexible user experience than traditional APC applications, making operators and engineers far more effective and productive." During this half-day seminar, Hector Buchelly, Global Director of Turbo Machinery, Invensys and a team of experts will explain methods and technologies to help you achieve your operational and business objectives. They will examine TMC control platforms and compare and contrast configurations and installations. The focus will be on how you can significantly boost performance, safety, and productivity.

During this half-day seminar, Hector Buchelly, Global Director of Turbo Machinery, Invensys and a team of experts will explain methods and technologies to help you achieve your operational and business objectives. They will examine TMC control platforms and compare and contrast configurations and installations. The focus will be on how you can significantly boost performance, safety, and productivity. The Fieldbus Foundation has announced the postponement of its 2014 General Assembly in Rotterdam due to travel and security restrictions associated with the upcoming Global Nuclear Security Summit (NSS) in The Hague, The Netherlands.

The Fieldbus Foundation has announced the postponement of its 2014 General Assembly in Rotterdam due to travel and security restrictions associated with the upcoming Global Nuclear Security Summit (NSS) in The Hague, The Netherlands.