SNC-Lavalin Group Inc. (TSX: SNC) (SNC-Lavalin) is pleased to announce that it has reached an agreement with Kentz Corporation Limited (Kentz), approved by the boards of directors of both companies, on the terms of a cash acquisition by which the entire ordinary share capital of Kentz--issued and to be issued--will be acquired by SNC-Lavalin. Kentz is a global oil & gas services company, with 14,500 employees operating in 36 countries who provide engineering, construction and technical support services to clients in the oil & gas sector. The full announcement was issued earlier publicly and may be viewed on SNC-Lavalin’s website.

SNC-Lavalin Group Inc. (TSX: SNC) (SNC-Lavalin) is pleased to announce that it has reached an agreement with Kentz Corporation Limited (Kentz), approved by the boards of directors of both companies, on the terms of a cash acquisition by which the entire ordinary share capital of Kentz--issued and to be issued--will be acquired by SNC-Lavalin. Kentz is a global oil & gas services company, with 14,500 employees operating in 36 countries who provide engineering, construction and technical support services to clients in the oil & gas sector. The full announcement was issued earlier publicly and may be viewed on SNC-Lavalin’s website.

The proposed acquisition of Kentz is fully aligned with SNC-Lavalin’s strategy of becoming a global Tier-1 engineering and construction (E&C) services firm. The addition of Kentz’s capabilities will make SNC-Lavalin a leading global E&C player in the oil & gas sector, with a greater presence in key growth regions, including the Middle East, North America and Asia Pacific, with a significant presence in Australia. The acquisition also meets the strategic priority of balancing the Company’s risk profile by significantly raising the percentage of revenues it derives from services. This has been supported by discussions between both parties and a robust due diligence process.

“We look forward to adding Kentz to our group and significantly strengthening our capabilities in the oil & gas sector,” said Robert G. Card, President and CEO, SNC-Lavalin Group Inc. “We are excited by the prospect of merging the excellent capabilities of our two oil & gas teams under the leadership of Christian Brown, Kentz’s CEO, which will create a world-class team inside of SNC-Lavalin to better serve our combined clients worldwide. This proposed acquisition and the agreement to sell AltaLink are important milestones in our stated strategy for growth. Together, they give us confidence to increase our focus on the disposition of other mature assets. ” he added.

“On behalf of our Board I am pleased to announce SNC-Lavalin’s recommended cash offer to our shareholders, which has received unanimous support from our Board members. We feel that the Offer recognizes the value of our future prospects, world-class client base, and our excellent people; the ultimate assets of our business. It also offers certainty, in cash, to Kentz Shareholders today,” said Christian Brown, CEO, Kentz. “Our track record in providing complex engineering and construction solutions to the energy sector globally, has evolved considerably from our first international projects in the 1970s, and many of the people instrumental to our growth remain with us today. We have a bright future and I believe that SNC-Lavalin’s technical abilities and scale can support our continued success and bring further benefits to our employees, clients, and partners. I would like to extend my personal gratitude to all of the people that make Kentz what it is and look forward to continuing our success together.”

Adidas

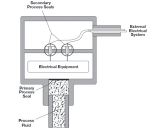

White Paper by Magnetrol: Over the years, well defined standards have been established to address the requirements for process sealing between electrical system and process fluids, where a failure could allow migration of fluid into the electrical system. The primary audience for this are the users of the process operators and facilities and installers of electrical system and instrumentation.

White Paper by Magnetrol: Over the years, well defined standards have been established to address the requirements for process sealing between electrical system and process fluids, where a failure could allow migration of fluid into the electrical system. The primary audience for this are the users of the process operators and facilities and installers of electrical system and instrumentation. Engineers designing machinery safety systems can now more easily collaborate across multiple languages using the Safety Automation Builder software tool from Rockwell Automation. The software – designed to help engineers save time when designing safety systems – has been downloaded more than 15,000 times since its launch in February 2013. It also was named one of the top 10 most innovative products at last year's SPS Drives show in Germany.

Engineers designing machinery safety systems can now more easily collaborate across multiple languages using the Safety Automation Builder software tool from Rockwell Automation. The software – designed to help engineers save time when designing safety systems – has been downloaded more than 15,000 times since its launch in February 2013. It also was named one of the top 10 most innovative products at last year's SPS Drives show in Germany. Yokogawa Electric Corporation announces that it has concluded a strategic partnership agreement with Rosneft. The agreement was signed on June 16 at the 21st World Petroleum Congress. Under this agreement, Rosneft will on a tender basis consider Yokogawa as a vendor of automated process control systems for the Company’s subsidiaries.

Yokogawa Electric Corporation announces that it has concluded a strategic partnership agreement with Rosneft. The agreement was signed on June 16 at the 21st World Petroleum Congress. Under this agreement, Rosneft will on a tender basis consider Yokogawa as a vendor of automated process control systems for the Company’s subsidiaries. Schneider Electric, the global specialist in energy management, has released a powerful new HMI software product as part of its market-leading Wonderware® InTouch® portfolio. Designed to run with modest hardware requirements and operable on embedded versions of Microsoft Windows operating systems, InTouch Machine Edition software is tailored to meet the needs of end users, OEMs and machine and system builders while giving them scalability and tight integration with Wonderware Historian and Wonderware System Platform. Because it can directly connect to industrial data sources, the new software enables users to access the information they need to improve plant operations and lower total cost of ownership in real time.

Schneider Electric, the global specialist in energy management, has released a powerful new HMI software product as part of its market-leading Wonderware® InTouch® portfolio. Designed to run with modest hardware requirements and operable on embedded versions of Microsoft Windows operating systems, InTouch Machine Edition software is tailored to meet the needs of end users, OEMs and machine and system builders while giving them scalability and tight integration with Wonderware Historian and Wonderware System Platform. Because it can directly connect to industrial data sources, the new software enables users to access the information they need to improve plant operations and lower total cost of ownership in real time. C-more b AutomationDirect 8" and 10" Micro-Graphic panels are full color, TFT models that offer touch screen capability and customizable graphics. In addition to the simple panel configuration software, a very helpful feature is the built-in project simulator. The project simulator allows you to view your project on the PC screen as it would appear on the panel and to test all your screens before downloading the project to the panel. You can simulate your entire project at any stage of development and even simulate the function keys and keypad bezel.

C-more b AutomationDirect 8" and 10" Micro-Graphic panels are full color, TFT models that offer touch screen capability and customizable graphics. In addition to the simple panel configuration software, a very helpful feature is the built-in project simulator. The project simulator allows you to view your project on the PC screen as it would appear on the panel and to test all your screens before downloading the project to the panel. You can simulate your entire project at any stage of development and even simulate the function keys and keypad bezel. Honeywell Resins and Chemicals has introduced a new Aegis® nylon resin designed to protect cables and electrical wiring used in industrial and consumer products.

Honeywell Resins and Chemicals has introduced a new Aegis® nylon resin designed to protect cables and electrical wiring used in industrial and consumer products. HIMA has expanded its HIMax safety system product line, adding a new CPU especially for small and mid-range safety applications. Announced in late 2013, the new X-CPU 31 module is now available worldwide, complementing the HIMax system family for safe and nonstop plant operation.

HIMA has expanded its HIMax safety system product line, adding a new CPU especially for small and mid-range safety applications. Announced in late 2013, the new X-CPU 31 module is now available worldwide, complementing the HIMax system family for safe and nonstop plant operation.