CAS DataLoggers and Jager are proud to introduce a new processor board for ADwin-Pro-II Data Acquisition and Control Systems which has a 64-bit FPU (Floating-Point Unit) for math co-processing. The new Pro-CPU-T12 processor module offers powerful real-time computing and is largely software-compatible to previous versions. With Ethernet support enabling high-speed data transfer, ADwin’s Pro-CPU-T12 module enables standalone data recording in applications where there’s no PC or connection to one. This powerful solution is ideal for satisfying the most demanding applications including physics experiments, vibration monitoring, failure analysis, and high-speed data acquisition.

CAS DataLoggers and Jager are proud to introduce a new processor board for ADwin-Pro-II Data Acquisition and Control Systems which has a 64-bit FPU (Floating-Point Unit) for math co-processing. The new Pro-CPU-T12 processor module offers powerful real-time computing and is largely software-compatible to previous versions. With Ethernet support enabling high-speed data transfer, ADwin’s Pro-CPU-T12 module enables standalone data recording in applications where there’s no PC or connection to one. This powerful solution is ideal for satisfying the most demanding applications including physics experiments, vibration monitoring, failure analysis, and high-speed data acquisition.

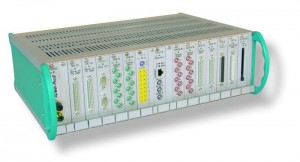

The Heart of the ADwin-Pro II System

The processor module--the ADwin CPU--is the center of each ADwin-Pro II data acquisition system. It executes the ADbasic programming instructions and accesses the inputs, outputs and interfaces of the other modules.

ADwin’s new Pro-CPU-T12 processor offers powerful Giga-performance, with a 1 Gigahertz clock, 1-Gigabyte main memory for storing code and data, and a 1-Gigabit Ethernet interface for communication to the PC. All this makes the 64-Bit double-precision FPU 5x faster than its predecessor module the CPU-T11. The T12 module also has a trigger input and 2 Digital I/Os, and as a special feature the board can also run C code embedded into ADbasic code. The module also enables stand-alone operation without a PC using the Bootloader.

Flexible Access:

Users have the choice of either USB or a SATA storage device on the module: the SATA device can either be integrated into the module or removable. Access to the memory is provided via processor module or via NFS/SMB/FTP from the Ethernet network.

ADwin data acquisition systems feature tightly-coupled analog and digital inputs along with counters to provide users’ applications with extremely low-latency operation. The ADwin-Pro II Series utilizes a modular form factor with plug-in modules to allow up to 480 analog or digital inputs in a single chassis, along with a high-performance 300 MHz DSP processor and Ethernet communications interface. Users also have a variety of other I/O options including CANbus, SSI, Profibus/Fieldbus, RS-232/485, and signal conditioner modules.

The extraordinary speed of the Pro-II system provides complex applications with a high data rate while the fast processor allows an intelligent pre-selection of relevant data, mathematical functions or digital channel filtering.

Nike

Chevron’s Ghent facility in Belgium blends Texaco branded lubricants. The plant has over fifty vessels and storage tanks, and currently produces more than fifty formulations of lubricants and viscosity index improvers by means of blending and additives. Product quality is rigorously controlled. Approximately 1,000 tests are performed weekly at the plant’s analysis laboratory. More than thirty truck shipments are made every week. The plant previously was controlled by a Unix-based Foxboro I/A series distributed control system (DCS) installed in 1997. In 2010, Chevron decided to migrate to a new platform to take advantage of new functionalities, and ensure it had a system commensurate with its strong value proposition of advanced technology.

Chevron’s Ghent facility in Belgium blends Texaco branded lubricants. The plant has over fifty vessels and storage tanks, and currently produces more than fifty formulations of lubricants and viscosity index improvers by means of blending and additives. Product quality is rigorously controlled. Approximately 1,000 tests are performed weekly at the plant’s analysis laboratory. More than thirty truck shipments are made every week. The plant previously was controlled by a Unix-based Foxboro I/A series distributed control system (DCS) installed in 1997. In 2010, Chevron decided to migrate to a new platform to take advantage of new functionalities, and ensure it had a system commensurate with its strong value proposition of advanced technology. Yokogawa Electric Corporation announces the release on this date of CENTUM® VP R5.04, an enhanced version of the company’s flagship integrated production control system. This new CENTUM release features enhanced alarm and batch functions.

Yokogawa Electric Corporation announces the release on this date of CENTUM® VP R5.04, an enhanced version of the company’s flagship integrated production control system. This new CENTUM release features enhanced alarm and batch functions. Kepware Technologies, a software development company focused on communications for automation, today announced major product updates to KEPServerEX version 5.15. The release demonstrates Kepware's unwavering commitment to communications standards and support of industry-leading hardware manufacturers. The updates are particularly relevant to customers in the Manufacturing, Building Automation, and Energy Management markets.

Kepware Technologies, a software development company focused on communications for automation, today announced major product updates to KEPServerEX version 5.15. The release demonstrates Kepware's unwavering commitment to communications standards and support of industry-leading hardware manufacturers. The updates are particularly relevant to customers in the Manufacturing, Building Automation, and Energy Management markets. Rotork’s innovative CVA electric control valve actuators are enabling the Sydney Water Corporation in Australia to control the pressure in the city’s water supply network with greatly increased response and accuracy.

Rotork’s innovative CVA electric control valve actuators are enabling the Sydney Water Corporation in Australia to control the pressure in the city’s water supply network with greatly increased response and accuracy. Case Study by Emerson: Reliance Industries Ltd., ranked 99th on the Fortune 500 list of the world’s major corporations, operates the largest refinery and petrochemical complex. Located in Jamnagar, Gujarat, India, this refinery processes 1.24 million bpd (MMbpd) of crude oil. Largely due to this facility, Jamnagar has emerged as one of the world’s refining hubs. This refinery features the world’s largest crude distillation, fluid catalytic cracking, delayed coking and paraxylene (PX) units. The complex involves the operation of 50 various processing units to produce PX, ethylene, polyethylene, polypropylene, transportation fuels (diesel, gasoline and aviation fuels), and many other products.

Case Study by Emerson: Reliance Industries Ltd., ranked 99th on the Fortune 500 list of the world’s major corporations, operates the largest refinery and petrochemical complex. Located in Jamnagar, Gujarat, India, this refinery processes 1.24 million bpd (MMbpd) of crude oil. Largely due to this facility, Jamnagar has emerged as one of the world’s refining hubs. This refinery features the world’s largest crude distillation, fluid catalytic cracking, delayed coking and paraxylene (PX) units. The complex involves the operation of 50 various processing units to produce PX, ethylene, polyethylene, polypropylene, transportation fuels (diesel, gasoline and aviation fuels), and many other products. Yokogawa Electric Corporation has announced that its CENTUM® VP production control system has obtained the ISASecure® Embedded Device Security Assurance (EDSA) certification from the ISA Security Compliance Institute (ISCI).

Yokogawa Electric Corporation has announced that its CENTUM® VP production control system has obtained the ISASecure® Embedded Device Security Assurance (EDSA) certification from the ISA Security Compliance Institute (ISCI). Foster Wheeler AG (Nasdaq:FWLT) announced today that a subsidiary of its Global Engineering and Construction Group, in joint venture with Taknia Libya Engineering Company (Taknia), has been awarded a front-end engineering design (FEED) contract by Nafusah Oil Operations B.V. Libyan Branch for an onshore oilfield development, known as the Area 47 Development Project in Libya. Area 47 (North Hamada Field) is located in the Hamada region, approximately 200 km south of Tripoli, in the Ghadames Basin.

Foster Wheeler AG (Nasdaq:FWLT) announced today that a subsidiary of its Global Engineering and Construction Group, in joint venture with Taknia Libya Engineering Company (Taknia), has been awarded a front-end engineering design (FEED) contract by Nafusah Oil Operations B.V. Libyan Branch for an onshore oilfield development, known as the Area 47 Development Project in Libya. Area 47 (North Hamada Field) is located in the Hamada region, approximately 200 km south of Tripoli, in the Ghadames Basin. NI (Nasdaq: NATI), the provider of solutions that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced the NI SOM. It combines the Xilinx Zynq All Programmable system on a chip (SoC) with supporting components such as memory on a small PCB and features a complete middleware solution and ready-to-go Linux-based real-time operating system (RTOS) already integrated. The NI SOM gives design teams the customizability of a SOM without the increased time and risk of developing custom software.

NI (Nasdaq: NATI), the provider of solutions that enable engineers and scientists to solve the world’s greatest engineering challenges, today announced the NI SOM. It combines the Xilinx Zynq All Programmable system on a chip (SoC) with supporting components such as memory on a small PCB and features a complete middleware solution and ready-to-go Linux-based real-time operating system (RTOS) already integrated. The NI SOM gives design teams the customizability of a SOM without the increased time and risk of developing custom software.