Historical information is used by the Automation Industry to improve process throughput, manage assets, and report to regulatory authorities. Therefore, access to this information is critical. Both Operations and Engineering teams require solutions that can be located close to the data source, are capable of storing data at high speeds, and have the flexibility that teams need to efficiently respond to the requirements of the manufacturing line, drilling rig, test laboratory, pump station, or other industrial environment. Kepware Technologies' Local Historian Plug-In for KEPServerEX is a flexible, easy to use, and cost-effective solution that provides industry-leading trending, reporting, and analytics tools with access to historical data using OPC Historical Data Access (HDA).

Historical information is used by the Automation Industry to improve process throughput, manage assets, and report to regulatory authorities. Therefore, access to this information is critical. Both Operations and Engineering teams require solutions that can be located close to the data source, are capable of storing data at high speeds, and have the flexibility that teams need to efficiently respond to the requirements of the manufacturing line, drilling rig, test laboratory, pump station, or other industrial environment. Kepware Technologies' Local Historian Plug-In for KEPServerEX is a flexible, easy to use, and cost-effective solution that provides industry-leading trending, reporting, and analytics tools with access to historical data using OPC Historical Data Access (HDA).

A Local Historian can supplement the existing Enterprise Historian model used in most large-scale industrial environments like Manufacturing, Oil & Gas, and Utilities. Although the Enterprise Historian will continue to have a place in large companies as the final perpetual archive of critical information, many organizations also have a need for a smaller, more flexible historian application that is easy to configure and provides open access to third-party analysis and reporting tools at the point of collection.

Kepware's Local Historian Plug-In leverages the KEPServerEX communications platform to transport information to its high-speed datastore. The Local Historian provides historical information to custom or off-the-shelf OPC HDA-compliant client applications for data visualization, reporting, and analytics. Because the Local Historian's design decouples data storage and visualization, users can choose the visualization or reporting solution that best meets their unique needs.

Kepware has tested the plug-in with multiple third-party trending and reporting products to validate its OPC HDA implementation and ensure a seamless user experience. One of the reporting products with which Kepware has completed testing includes XLReporter from SyTech.

"Kepware's Local Historian is a robust historian backed by Kepware's long experience in the automation field," said Peter Kaprielian, CTO, SyTech. "It has been fully tested with XLReporter and both products work seamlessly together. We, along with Kepware, are committed to providing high-quality support for our products."

The Local Historian Plug-In supports high-speed logging to 10 milliseconds and tiered licensing for up to ten thousand tags. Open standards allow locally-stored data to be accessed from multiple clients with no additional cost per client connection.

Air Force 1 Low Upstep BR

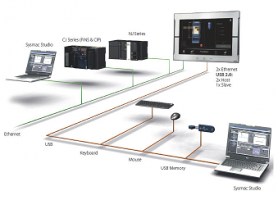

The Omron Sysmac HMI enables faster, more efficient control and monitoring - and a more natural, proactive relationship between operator and machine. Wide screen models: 7, 9, 12 and 15 inches. An HMI that is dynamic, intuitive and predictive makes industrial machines more attractive and competitive. The Omron HMI enables faster, more efficient control and monitoring - and a more natural, proactive relationship between operator and machine. The design has been based on real applications and customer requirements, a future-proofed, scalable platform that will evolve with their ever-changing needs, allowing real time reaction to events. As part of the system family, the NA Series is fully aware of the total machine.

The Omron Sysmac HMI enables faster, more efficient control and monitoring - and a more natural, proactive relationship between operator and machine. Wide screen models: 7, 9, 12 and 15 inches. An HMI that is dynamic, intuitive and predictive makes industrial machines more attractive and competitive. The Omron HMI enables faster, more efficient control and monitoring - and a more natural, proactive relationship between operator and machine. The design has been based on real applications and customer requirements, a future-proofed, scalable platform that will evolve with their ever-changing needs, allowing real time reaction to events. As part of the system family, the NA Series is fully aware of the total machine.

Moore Industries has published a new white paper on an application using the WORM Flexible Temperature Sensors to measure the temperature of molasses during the production of beet sugar. Using the WORM as a replacement for standard thermowells allows site engineers to get more accurate temperature readings and maximize the amount of sugar recovered from the molasses.

Moore Industries has published a new white paper on an application using the WORM Flexible Temperature Sensors to measure the temperature of molasses during the production of beet sugar. Using the WORM as a replacement for standard thermowells allows site engineers to get more accurate temperature readings and maximize the amount of sugar recovered from the molasses. KBR Inc.has announced today that its joint venture partnership with PT Rekayasa Industri, JGC Corporation and PT JGC Indonesia, the RJK JV, has been awarded the onshore front-end engineering and design (FEED) contract by BP for a third liquefaction train at the Tangguh LNG Project in West Papua province, Indonesia.

KBR Inc.has announced today that its joint venture partnership with PT Rekayasa Industri, JGC Corporation and PT JGC Indonesia, the RJK JV, has been awarded the onshore front-end engineering and design (FEED) contract by BP for a third liquefaction train at the Tangguh LNG Project in West Papua province, Indonesia. Technip, in a joint venture with Fluor Corporation, has been awarded an engineering, procurement, and construction management (EP&CM) contract by Sasol for its world scale ethane cracker and derivatives complex near Lake Charles, Louisiana, USA. The new complex will be a major expansion to Sasol’s existing Lake Charles Chemical Complex and will be constructed adjacent to its existing facility in southwest Louisiana. Under this contract, the Technip and Fluor joint venture will be responsible for a 1.5 million-tons-per-year ethane cracker, downstream derivatives units and associated utilities, offsites and infrastructure work.

Technip, in a joint venture with Fluor Corporation, has been awarded an engineering, procurement, and construction management (EP&CM) contract by Sasol for its world scale ethane cracker and derivatives complex near Lake Charles, Louisiana, USA. The new complex will be a major expansion to Sasol’s existing Lake Charles Chemical Complex and will be constructed adjacent to its existing facility in southwest Louisiana. Under this contract, the Technip and Fluor joint venture will be responsible for a 1.5 million-tons-per-year ethane cracker, downstream derivatives units and associated utilities, offsites and infrastructure work. Rosemount Analytical is the leader in oxygen flue gas analyzer technology. The 6888 continues the tradition of integrating an oxygen probe and field electronics into a single, compact package. The probe inserts directly into a flue gas duct to measure oxygen in combustion processes. No sampling system is required, and the newest version offers an optional on-line automatic calibration capability embedded within the probe, freeing up your technician’s time, and ensuring the most accurate O2 readings over time.

Rosemount Analytical is the leader in oxygen flue gas analyzer technology. The 6888 continues the tradition of integrating an oxygen probe and field electronics into a single, compact package. The probe inserts directly into a flue gas duct to measure oxygen in combustion processes. No sampling system is required, and the newest version offers an optional on-line automatic calibration capability embedded within the probe, freeing up your technician’s time, and ensuring the most accurate O2 readings over time. Advantech’s new 12.1” and 15” TPC-1251T/1551T touch panel computers are the latest of their type to use the Intel® Atom™ E3827 1.75 GHz Processor, and to feature the much heralded iDoor Technology, a truly flat screen and a multitude of I/O ports whilst being able to operate in a wide range of temperatures..

Advantech’s new 12.1” and 15” TPC-1251T/1551T touch panel computers are the latest of their type to use the Intel® Atom™ E3827 1.75 GHz Processor, and to feature the much heralded iDoor Technology, a truly flat screen and a multitude of I/O ports whilst being able to operate in a wide range of temperatures.. Historical information is used by the Automation Industry to improve process throughput, manage assets, and report to regulatory authorities. Therefore, access to this information is critical. Both Operations and Engineering teams require solutions that can be located close to the data source, are capable of storing data at high speeds, and have the flexibility that teams need to efficiently respond to the requirements of the manufacturing line, drilling rig, test laboratory, pump station, or other industrial environment. Kepware Technologies' Local Historian Plug-In for KEPServerEX is a flexible, easy to use, and cost-effective solution that provides industry-leading trending, reporting, and analytics tools with access to historical data using OPC Historical Data Access (HDA).

Historical information is used by the Automation Industry to improve process throughput, manage assets, and report to regulatory authorities. Therefore, access to this information is critical. Both Operations and Engineering teams require solutions that can be located close to the data source, are capable of storing data at high speeds, and have the flexibility that teams need to efficiently respond to the requirements of the manufacturing line, drilling rig, test laboratory, pump station, or other industrial environment. Kepware Technologies' Local Historian Plug-In for KEPServerEX is a flexible, easy to use, and cost-effective solution that provides industry-leading trending, reporting, and analytics tools with access to historical data using OPC Historical Data Access (HDA). Rockwell Automation has announced it has purchased the assets of ESC Services, Inc., a global hazardous energy control provider of lockout-tagout services and solutions.

Rockwell Automation has announced it has purchased the assets of ESC Services, Inc., a global hazardous energy control provider of lockout-tagout services and solutions.