Exida, one of the leading certification bodies for functional safety and security standards, assessed RPC Radiy’s RadICS FPGA-Based Safety Controller (FSC) per the relevant requirements of IEC 61508:2010, parts 1-7 and found that it meets requirements providing Safety Integrity Level (SIL) 3.

Radiy’s RadICS FSC will read input signals, perform user-defined application layer logic and write results to the output signals within the stated response time. The FSC can be used for design and development of SIL 3 level applications.

“Radiy has developed unique technology that utilizes FPGAs to implement logic solver capabilities,” said Dave Butler, exida evaluating assessor. “Their strong development process ensures the delivery of products that achieve high levels of functional safety.”

The following is from the exida assessment report:

“The audited development process as tailored and implemented for the RPC Radiy FPGA-based Safety Controller (FSC) RadICS development project, complies with the relevant safety management requirements of IEC 61508 SIL 3.

“The assessment of the FMEDA, done to the requirements of IEC 61508, has shown that the FPGA-based Safety Controller (FSC) RadICS can be used in a Low Demand safety related system in a manner where the calculated PFD AVG is within the allowed range for SIL 3 (HFT >= 0) according to table 2 of IEC 61508-1.

The RadICS platform (see Fig. 1) is a set of general-purpose building blocks that can be configured and used to implement application-specific functions and systems. The RadICS platform is composed of various standardized modules, each based on the use of FPGA chips as computational engines.

The basic configuration for the RadICS platform consists of an instrument rack containing two logic modules, as well as up to 14 other I/O modules and fibre-optic communication modules. Logic modules gather input data from input modules, execute user-specified logic, and update the value driving the output modules, as well as gather diagnostic and general health information from all I/O modules. The I/O modules provide interfaces with field devices (for example, sensors, transmitters, actuators). The functionality of each module is driven by the logic implemented in the on-board FPGA(s).

The basic set of I/O modules consists of analogue and digital input, and digital output modules. There are also special-purpose I/O boards designed for specific field detectors and devices, such as resistance temperature detectors (RTDs), thermocouples, ultra-low voltage AI boards used for neutronic instrumentation, actuator controller modules, and fibre-optic communication modules that can be used to expand the I&C system to multiple chassis. It is also possible to provide inter-channel communications between 2, 3 or 4 channels via fibre-optic communications directly between logic modules.

The backplane of the RadICS platform provides external interfaces to power supply, process I/Os, communication links, and local inputs and indicators. The internal backplane interfaces provide connections to the various modules that are installed within the chassis by means of a dedicated, isolated, point-to-point low-voltage differential signalling (LVDS) interface.

Nike Air Max

Yokogawa Electric Corporation announces the development of the SMARTDAC+® GX20W wireless paperless recorder. This new product supports the ISA100 Wireless™ industrial automation wireless communication standard and is expected to become an essential component of the SMARTDAC+ data acquisition and control system. The GX20W will be released to the market on November 12.

Yokogawa Electric Corporation announces the development of the SMARTDAC+® GX20W wireless paperless recorder. This new product supports the ISA100 Wireless™ industrial automation wireless communication standard and is expected to become an essential component of the SMARTDAC+ data acquisition and control system. The GX20W will be released to the market on November 12.

KBR has announced that it has been awarded a front-end engineering design (FEED) contract by Saudi Basic Industries Corporation (SABIC) for the debottlenecking and expansion of its Petrokemya Butadiene Extraction Plant in Al Jubail, Saudi Arabia.

KBR has announced that it has been awarded a front-end engineering design (FEED) contract by Saudi Basic Industries Corporation (SABIC) for the debottlenecking and expansion of its Petrokemya Butadiene Extraction Plant in Al Jubail, Saudi Arabia. The latest release of FactoryTalk Batch software from Rockwell Automation eases the process of modifying and creating new recipes by managing the approval process for changes and automatically tracking the genealogy of recipes. New security-authority binding features also help manufacturers protect their intellectual property.

The latest release of FactoryTalk Batch software from Rockwell Automation eases the process of modifying and creating new recipes by managing the approval process for changes and automatically tracking the genealogy of recipes. New security-authority binding features also help manufacturers protect their intellectual property. ABB, the leading power and automation group, announced today it completed its acquisition of Spirit IT of Eindhoven, Netherlands. The acquisition, announced July 25, adds a new line of high-performance liquid flow computers, SCADA and custody transfer solutions to ABB’s leading measurement business for the oil and gas industry.

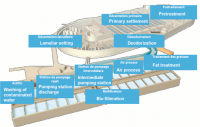

ABB, the leading power and automation group, announced today it completed its acquisition of Spirit IT of Eindhoven, Netherlands. The acquisition, announced July 25, adds a new line of high-performance liquid flow computers, SCADA and custody transfer solutions to ABB’s leading measurement business for the oil and gas industry. Case Study by Yokogawa: Constructed in 1987, the GEOLIDE wastewater purification plant treats up to 220,000 m3 of wastewater per day (86 million m3 per year) for the city of Marseille (population 1,860,000) and 16 towns in the surrounding area. The plant has been operated since 2001 by Seramm, which is a subsidiary of the French water supply and wastewater treatment company Lyonnaise des Eaux.

Case Study by Yokogawa: Constructed in 1987, the GEOLIDE wastewater purification plant treats up to 220,000 m3 of wastewater per day (86 million m3 per year) for the city of Marseille (population 1,860,000) and 16 towns in the surrounding area. The plant has been operated since 2001 by Seramm, which is a subsidiary of the French water supply and wastewater treatment company Lyonnaise des Eaux. Rapidly changing consumer demands require machine and equipment builders to reduce development and installation time while increasing machine flexibility. The Allen-Bradley Kinetix 5500 servo drive with integrated safety can help machine builders satisfy those requirements by taking advantage of a single EtherNet/IP network, as well as a common design environment with Rockwell Software Studio 5000 Logix Designer software.

Rapidly changing consumer demands require machine and equipment builders to reduce development and installation time while increasing machine flexibility. The Allen-Bradley Kinetix 5500 servo drive with integrated safety can help machine builders satisfy those requirements by taking advantage of a single EtherNet/IP network, as well as a common design environment with Rockwell Software Studio 5000 Logix Designer software. Technip was awarded by Sasol a contract to provide engineering and procurement for eight proprietary Ultra Selective Conversion (USC®) furnaces (1) for a world-scale ethane cracker and derivatives complex to be located in Lake Charles, Louisiana, USA. The award follows Sasol’s selection of Technip’s proprietary ethylene technology and FEED (2) for the cracker, which will produce an estimated 1.5 million tons per annum of ethylene.

Technip was awarded by Sasol a contract to provide engineering and procurement for eight proprietary Ultra Selective Conversion (USC®) furnaces (1) for a world-scale ethane cracker and derivatives complex to be located in Lake Charles, Louisiana, USA. The award follows Sasol’s selection of Technip’s proprietary ethylene technology and FEED (2) for the cracker, which will produce an estimated 1.5 million tons per annum of ethylene.