The state-owned oil company of Suriname, Staatsolie Maatschappij Suriname N.V., will use Honeywell’s manufacturing execution system (MES) as part of a major expansion and efficiency project it is planning at the Tout Lui Faut crude oil refinery complex. The project will more than double the refinery’s capacity of high-quality diesel, gasoline and fuel oil, greatly reducing the country’s dependence on imported fuel products.

The state-owned oil company of Suriname, Staatsolie Maatschappij Suriname N.V., will use Honeywell’s manufacturing execution system (MES) as part of a major expansion and efficiency project it is planning at the Tout Lui Faut crude oil refinery complex. The project will more than double the refinery’s capacity of high-quality diesel, gasoline and fuel oil, greatly reducing the country’s dependence on imported fuel products.

Honeywell’s MES will help the refinery better manage its production, operations and process visualization using multiple Honeywell-developed applications for data collection, operations planning, execution and monitoring, real-time asset management, electronic maintenance and reliability systems, and production balance.

“With the Honeywell MES solution, our refinery expects to achieve significantly improved operational readiness,” said Rudolf Elias, project director and acting director for Refining and Marketing at Staatsolie. “Honeywell’s manufacturing and business applications provide the tools we need, allowing us to optimize workflows, capture knowledge, minimize risks, improve safety, and enhance the performance and agility of our entire operation.”

Sneaker

Case Study by Yokogawa: PT. Tanjung Enim Lestari Pulp and Paper (PT. TEL) operates a pulp mill in Muara Enim, which is 130 km west of Palembang, the capital of Indonesia’s South Sumatra province. This is the only pulp mill in the world to produce high-quality, bleached-hardwood kraft pulp solely from plantation grown Acacia mangium trees. Using a single vessel hydraulic type continuous digester that is designed for lo-solids cooking, the pulp mill produces 500,000 tons of pulp per year, making it one of the largest mills in southeast Asia.

Case Study by Yokogawa: PT. Tanjung Enim Lestari Pulp and Paper (PT. TEL) operates a pulp mill in Muara Enim, which is 130 km west of Palembang, the capital of Indonesia’s South Sumatra province. This is the only pulp mill in the world to produce high-quality, bleached-hardwood kraft pulp solely from plantation grown Acacia mangium trees. Using a single vessel hydraulic type continuous digester that is designed for lo-solids cooking, the pulp mill produces 500,000 tons of pulp per year, making it one of the largest mills in southeast Asia. Success Story by Yokogawa: SAMSUNG Fine Chemicals (SFC) produces many kinds of fine chemicals that have been well received both in Korea and the global market. SFC’s products include mecellose (methylcellulose), epichlorohydrin (ECH), dimethylformamide (DMF), methylamines, tetramethylammonium chloride (TMAC), barium titanate powder (BTP), and AnyCoat. SFC also produces a range of general chemical products such as ammonia, urea, melamine, methylene chloride, methyl chloride, formic acid, and caustic soda. One of SFC’s primary next-generation strategic businesses is the production of electronic chemical materials (ECM) such as BTP.

Success Story by Yokogawa: SAMSUNG Fine Chemicals (SFC) produces many kinds of fine chemicals that have been well received both in Korea and the global market. SFC’s products include mecellose (methylcellulose), epichlorohydrin (ECH), dimethylformamide (DMF), methylamines, tetramethylammonium chloride (TMAC), barium titanate powder (BTP), and AnyCoat. SFC also produces a range of general chemical products such as ammonia, urea, melamine, methylene chloride, methyl chloride, formic acid, and caustic soda. One of SFC’s primary next-generation strategic businesses is the production of electronic chemical materials (ECM) such as BTP. White Paper by Motorola: With the wide range of RTU (Remote Terminal units) and PLC (Programmable Logic Controllers) currently on the market, SCADA system engineers and decision makers face several challenges. Which classes of units provide the optimal functionality, expandability, and cost effectiveness for a given SCADA application?

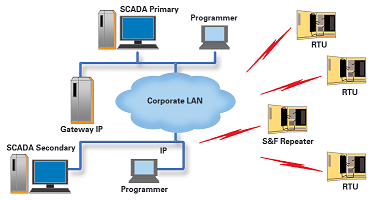

White Paper by Motorola: With the wide range of RTU (Remote Terminal units) and PLC (Programmable Logic Controllers) currently on the market, SCADA system engineers and decision makers face several challenges. Which classes of units provide the optimal functionality, expandability, and cost effectiveness for a given SCADA application? Yokogawa Success Story: PT PLN is a government-owned company that manages the electric power industry in Indonesia. To ensure a stable power supply for North Sulawesi province, PT PLN has built and currently operates four geothermal power plants in Lahendong, which is located 30 km south of Manado, the provincial capital. The two newest plants, Lahendong III and Lahendong IV, each produce 20 MW of electricity, and the financing for their construction was provided by the Japanese government’s Official Development Assistance (ODA) program and the Asia Development Bank (ADB), respectively.

Yokogawa Success Story: PT PLN is a government-owned company that manages the electric power industry in Indonesia. To ensure a stable power supply for North Sulawesi province, PT PLN has built and currently operates four geothermal power plants in Lahendong, which is located 30 km south of Manado, the provincial capital. The two newest plants, Lahendong III and Lahendong IV, each produce 20 MW of electricity, and the financing for their construction was provided by the Japanese government’s Official Development Assistance (ODA) program and the Asia Development Bank (ADB), respectively.