Chemical products are a key part of everyday life with more than 100,000 substances available and in use around the world. According to data from the UN Environment Program (UNEP), the global chemical industry produces more than 400 million tons of hazardous waste annually. These residues can present a severe threat to health and the environment if not discarded safely and quickly.

Chemical products are a key part of everyday life with more than 100,000 substances available and in use around the world. According to data from the UN Environment Program (UNEP), the global chemical industry produces more than 400 million tons of hazardous waste annually. These residues can present a severe threat to health and the environment if not discarded safely and quickly.

Chemical company BASF is tackling this challenge in an innovative way: converting chemical waste into reusable energy. The company recently upgraded its central waste incineration plant, which processes all the chemical waste from its site in Ludwigshafen, Germany, the largest chemical production site in the world with more than 250 plants, as well as from outside of the complex. The upgrade completely modernized the 60-year-old incineration control room with our Experion technology.

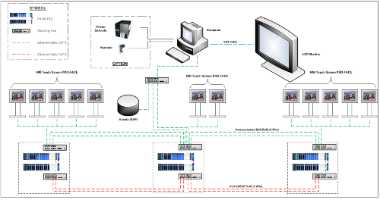

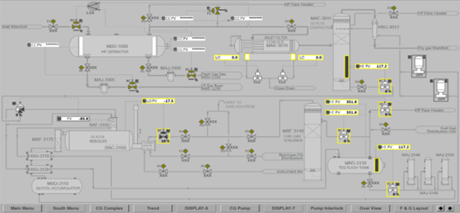

Nearly 30 controllers were installed to handle thousands of input and output signals from the incineration process each day. These signals help plant operators monitor the temperature, flow, level and pressure of the combustion process used on hazardous chemical waste. Once the waste is burned, the generated heat is converted into steam, which is then placed under high pressure in turbines to generate electricity—turning hazardous waste into clean energy.

Fully integrated into the consoles are live video feeds from several points of the incineration plant such as the boiler, combustion chamber and turbine. Barco OpSpace provides integration of video and interactive (third-party) computer sources into the Experion Orion console workspace, with control from one keyboard and mouse. A complete visualization of operations at any given moment offering insight into the incineration process from the beginning to the end.

Operators and production staff use two Collaboration Stations to access a large variety of plant information and documentation in real time — for example electricity and steam reports that provide important updates about how effectively the plant is converting hazardous waste into clean energy.

The incineration plant is responsible for burning hazardous chemical waste that cannot be recycled or reused in other production processes. These residues are introduced into the plant via pipelines, tanks and containers – mostly from the site itself but also from other nearby facilities. With these systems, plant operators monitor and control devices and equipment, while continuously receiving information on variables such as temperature, pressure and flow.

SFC Excellence Co., Ltd, a subsidiary of The Siam Chemicals Public Company (SCC), was found in 1975 and has registered capital of 70 million baht. SFC Excellence is exceptionally well-known for its manufacturing products and considered to be one of the largest importers of base oil and lube oil manufacturing (toll blenders) in Thailand. SFC Excellence is able to produce the best quality of lubricants for automotive and machineries in industrial usage with a total capacity of 10 million liters per month.

SFC Excellence Co., Ltd, a subsidiary of The Siam Chemicals Public Company (SCC), was found in 1975 and has registered capital of 70 million baht. SFC Excellence is exceptionally well-known for its manufacturing products and considered to be one of the largest importers of base oil and lube oil manufacturing (toll blenders) in Thailand. SFC Excellence is able to produce the best quality of lubricants for automotive and machineries in industrial usage with a total capacity of 10 million liters per month. This project was conducted for PTT Aromatics and Refining Public Company Limited (PTTAR), which was established in September 2007 through the amalgamation of Aromatics (Thailand) Public Company Limited (ATC) and Rayong Refinery Public Company Limited (RRC) and was Thailand’s no.1 integrated oil refiner and aromatics producer. In October 2011, PTTAR was amalgamated with PTT Chemical Public Company Limited to form the current PTT Global Chemical Public Company Limited.

This project was conducted for PTT Aromatics and Refining Public Company Limited (PTTAR), which was established in September 2007 through the amalgamation of Aromatics (Thailand) Public Company Limited (ATC) and Rayong Refinery Public Company Limited (RRC) and was Thailand’s no.1 integrated oil refiner and aromatics producer. In October 2011, PTTAR was amalgamated with PTT Chemical Public Company Limited to form the current PTT Global Chemical Public Company Limited. Chevron Bangladesh is the largest natural gas producer in Bangladesh, who is supplying approximately 50 percent of Bangladesh’s natural gas consumption. Through subsidiaries, Chevron Bangladesh produces natural gas and condensate from three fields at Bibiyana, Jalalabad and Moulavi Bazar, in northeast of Bangladesh. Bibiyana Gas Plant is located at the Bibiyana field in Block 12 of the Habiganj District, Sylhet Division. The plant is approximately 150 kilometers in the northeast of Dhaka.

Chevron Bangladesh is the largest natural gas producer in Bangladesh, who is supplying approximately 50 percent of Bangladesh’s natural gas consumption. Through subsidiaries, Chevron Bangladesh produces natural gas and condensate from three fields at Bibiyana, Jalalabad and Moulavi Bazar, in northeast of Bangladesh. Bibiyana Gas Plant is located at the Bibiyana field in Block 12 of the Habiganj District, Sylhet Division. The plant is approximately 150 kilometers in the northeast of Dhaka. Construction of IFCo’s $1.8 billion plant began in March 2013. By late 2015, the new plant will begin producing between 1.5 and 2 million tons of nitrogen fertilizer each year. IFCo will be the first world-scale fertilizer plant built in the United States in nearly 25 years. Nitrogen fertilizer accounts for about 60 percent of global fertilizer use. The output of the IFCo plant will drastically reduce US dependence on imported fertilizer. In addition, a domestic fertilizer source will save farmers across the country millions of dollars annually.

Construction of IFCo’s $1.8 billion plant began in March 2013. By late 2015, the new plant will begin producing between 1.5 and 2 million tons of nitrogen fertilizer each year. IFCo will be the first world-scale fertilizer plant built in the United States in nearly 25 years. Nitrogen fertilizer accounts for about 60 percent of global fertilizer use. The output of the IFCo plant will drastically reduce US dependence on imported fertilizer. In addition, a domestic fertilizer source will save farmers across the country millions of dollars annually.