Moxa has announced the release of the MGate MB3660MGate_MB3660 series of high density Modbus gateways that convert between the Modbus TCP and Modbus RTU/ASCII protocols. The gateways can be accessed by up to 256 TCP master/client devices, or connect to 128 TCP slave/server devices simultaneously without decreasing performance. Each serial port can be connected with up to 31 serial devices. In addition, the MGate MB3660 gateways are designed with dual Ethernet interfaces and dual power modules for addressing redundancy concerns. This strong collection of benefits make the MGate MB3660 gateways a perfect fit for power monitoring, environmental monitoring, and data center infrastructure management (DCIM) in large-scale industrial applications.

Moxa has announced the release of the MGate MB3660MGate_MB3660 series of high density Modbus gateways that convert between the Modbus TCP and Modbus RTU/ASCII protocols. The gateways can be accessed by up to 256 TCP master/client devices, or connect to 128 TCP slave/server devices simultaneously without decreasing performance. Each serial port can be connected with up to 31 serial devices. In addition, the MGate MB3660 gateways are designed with dual Ethernet interfaces and dual power modules for addressing redundancy concerns. This strong collection of benefits make the MGate MB3660 gateways a perfect fit for power monitoring, environmental monitoring, and data center infrastructure management (DCIM) in large-scale industrial applications.

“The main characteristic shared by these applications is that they are required to collect data from a large number of Modbus devices. The MGate MB3660 can actively communicate and collect data with end devices continuously to obtain up-to-date information; a SCADA system can retrieve all of the data from end devices in just 1 second. By using a high density Modbus gateway, you no longer need to use large numbers of low-port-density Modbus gateways, which come with the added burden of extra wiring and installing hardware and software one gateway at a time,” said Sean Chen, product manager of Moxa’s Industrial Ethernet Gateway division. “Moxa’s MGate MB3660 is designed with innovative command learning, which allows the gateways to actively and continuously retrieve data from Modbus devices in parallel through all serial ports; you won’t even need to key in one Modbus command, resulting in a dramatic reduction in the amount of time a Modbus device needs to wait to be accessed.”

The MGate MB3660 Modbus gateways support redundancy for both the power input and Ethernet connection, and come with dual AC or DC power inputs built in for power redundancy, and dual Ethernet ports (that support the same IP or different IPs) for network redundancy. In addition, the MGate MB3660 series isolation model provides 2 kV isolation protection suitable for power substation applications.

WINTER BUNDLES

Rockwell Automation has expanded its portfolio of industrial Ethernet switches with the new Allen-Bradley Stratix 5410 industrial distribution switch. With four 10-gigabit Ethernet ports, the Stratix 5410 switch provides a high-performance connection to the rest of a facility’s network architecture. The switch can be used as a Layer 2 switch or a Layer 3 routing switch, which allows engineers to use it in various applications.

Rockwell Automation has expanded its portfolio of industrial Ethernet switches with the new Allen-Bradley Stratix 5410 industrial distribution switch. With four 10-gigabit Ethernet ports, the Stratix 5410 switch provides a high-performance connection to the rest of a facility’s network architecture. The switch can be used as a Layer 2 switch or a Layer 3 routing switch, which allows engineers to use it in various applications. As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise.

As industrial markets evolve to unlock the promise of the Internet of Things (IoT), Rockwell Automation and Cisco have announced new additions to their Converged Plantwide Ethernet (CPwE) architectures to help operations technology (OT) and information technology (IT) professionals address constantly changing security practices. The latest CPwE security expansions, featuring technology from both companies, include design guidance and validated architectures to help build a more secure network across the plant and enterprise. Schneider Electric, the global specialist in energy management and automation, has today announced a partnership with worldwide leader in networking, Cisco, to bring advanced networking and control system technologies to its customers. Cisco is focused on helping transform industrial customers by connecting people, processes, data and things. Schneider Electric will leverage the proven technologies from Cisco to help deliver its enhanced industrial automation solutions.

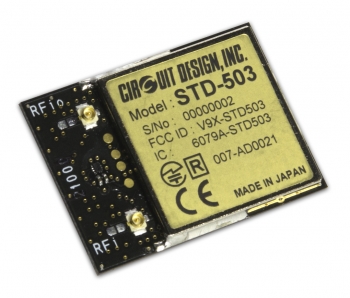

Schneider Electric, the global specialist in energy management and automation, has today announced a partnership with worldwide leader in networking, Cisco, to bring advanced networking and control system technologies to its customers. Cisco is focused on helping transform industrial customers by connecting people, processes, data and things. Schneider Electric will leverage the proven technologies from Cisco to help deliver its enhanced industrial automation solutions. Saelig Company, Inc. (www.saelig.com) has introduced the STD-503, a 2.4 GHz radio transceiver module, designed to facilitate the simple embedding of wireless capabilities in industrial remote control equipment. Suitable for worldwide implementation, this compact radio transceiver module was specifically developed for industrial applications that must have stable and reliable communication for up to 300 yards with battery operation.

Saelig Company, Inc. (www.saelig.com) has introduced the STD-503, a 2.4 GHz radio transceiver module, designed to facilitate the simple embedding of wireless capabilities in industrial remote control equipment. Suitable for worldwide implementation, this compact radio transceiver module was specifically developed for industrial applications that must have stable and reliable communication for up to 300 yards with battery operation.