Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs.

Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs.

Widely regarded as a leading innovator of clean and efficient energy solutions, ABB has undertaken this project in an effort to develop more environmentally-friendly fuels. As part of the operation, the company introduces several new wells on a daily basis that have between 50 and 70 data points being scanned on a 30 second cycle time. These requirements necessitate the ability to bring wells on and off line in a highly streamlined and efficient manner.

To ensure ABB could reliably configure these well sites and retrieve the vast amounts of data they produce, the company integrated Kepware's KEPServerEX communications platform. With its library of over 150 PLC, RTU, and device-type drivers, KEPServerEX helps users connect, manage, monitor, and control diverse automation devices and software applications through one user interface. Its robust functionality enabled ABB to scale the project without learning new communications protocols or introducing other applications. Furthermore, with the ability to import and export KEPServerEX configuration information in an easy-to-understand XML format, ABB has a simple, scalable, and reliable method for configuring new wells.

"With KEPServerEX, we were able to automate a traditionally manual process associated with bringing wells online—and with this particular project's expansion speed, we had no time physically to provision wells," said Mike Oakley, Consultant Engineer, ABB Ltd. "KEPServerEX worked seamlessly with our flagship control system so that a single button click would have the potential to bring hundreds of wells on or off line in mere minutes."

Air Max

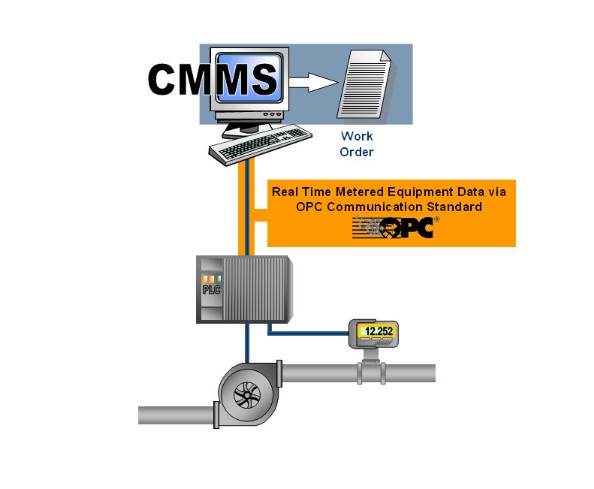

It takes Pacesetters two steps to optimize their maintenance efforts. First they automate their realtime data acquisition and storage using standards-based software applications. Second, they implement CBM systems that assess equipment health based on timely and accurate information. This enables Pacesetters to prioritize their maintenance efforts by moving human and capital resources away from well functioning equipment to areas that scream for early attention.

It takes Pacesetters two steps to optimize their maintenance efforts. First they automate their realtime data acquisition and storage using standards-based software applications. Second, they implement CBM systems that assess equipment health based on timely and accurate information. This enables Pacesetters to prioritize their maintenance efforts by moving human and capital resources away from well functioning equipment to areas that scream for early attention.

Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs.

Kepware Technologies, a software development company focused on communications for automation, announced today that leading power and automation company, ABB, has integrated KEPServerEX with its flagship product, 800xA Integrated Control and Safety System (ICSS). Selected as the main automation contractor for the world's first operation focused on converting gas from coal seams into liquefied natural gas, ABB utilizes Kepware's highly flexible and reliable communications platform to meet the project's demanding scalability needs. Power generation, transmission, and distribution utilities provide critical services to people every day. A proper redundant architecture can prevent failures from leading to loss of control or a disruption of electrical service. In order to ensure the constant operation of applications, industry leaders turn to OPC vendors and products like Matrikon OPC that provide mission critical redundancy.

Power generation, transmission, and distribution utilities provide critical services to people every day. A proper redundant architecture can prevent failures from leading to loss of control or a disruption of electrical service. In order to ensure the constant operation of applications, industry leaders turn to OPC vendors and products like Matrikon OPC that provide mission critical redundancy. Mirion Technologies has contracted with Schneider Electric to use its Wonderware eDNA historian software as the information management system for the Radiation Monitoring System (RMS) upgrade at AEP’s D.C. Cook nuclear power plant. The eDNA RadServ solution interfaces directly with Mirion’s radiation monitors being installed at the plant and is used to notify operators when radiation levels reach predefined thresholds.

Mirion Technologies has contracted with Schneider Electric to use its Wonderware eDNA historian software as the information management system for the Radiation Monitoring System (RMS) upgrade at AEP’s D.C. Cook nuclear power plant. The eDNA RadServ solution interfaces directly with Mirion’s radiation monitors being installed at the plant and is used to notify operators when radiation levels reach predefined thresholds. I have a 5 MB connection out to my remote sites in the field. For each site, I need to poll for status, alarm, and historical data. If I have one hundred sites, how fast can I poll each data set? How long will it take to send a control signal? Do I need to upgrade the connection? Downgrade?

I have a 5 MB connection out to my remote sites in the field. For each site, I need to poll for status, alarm, and historical data. If I have one hundred sites, how fast can I poll each data set? How long will it take to send a control signal? Do I need to upgrade the connection? Downgrade?