Yokogawa Electric Corporation (TOKYO: 6841) announced recently the release of the OpreX™ Asset Health Insights. A new addition to the OpreX Asset Management and Integrity family, Asset Health Insights is a cloud-based plant asset monitoring service that collects, refines, and aggregates operational technology (OT) data from distributed assets. The service offers a real-time connection with assets from anywhere in the world, giving organizations a 360-degree view of operational assets that eases the task of asset management and increases both operational and business efficiency.

Yokogawa Electric Corporation (TOKYO: 6841) announced recently the release of the OpreX™ Asset Health Insights. A new addition to the OpreX Asset Management and Integrity family, Asset Health Insights is a cloud-based plant asset monitoring service that collects, refines, and aggregates operational technology (OT) data from distributed assets. The service offers a real-time connection with assets from anywhere in the world, giving organizations a 360-degree view of operational assets that eases the task of asset management and increases both operational and business efficiency.

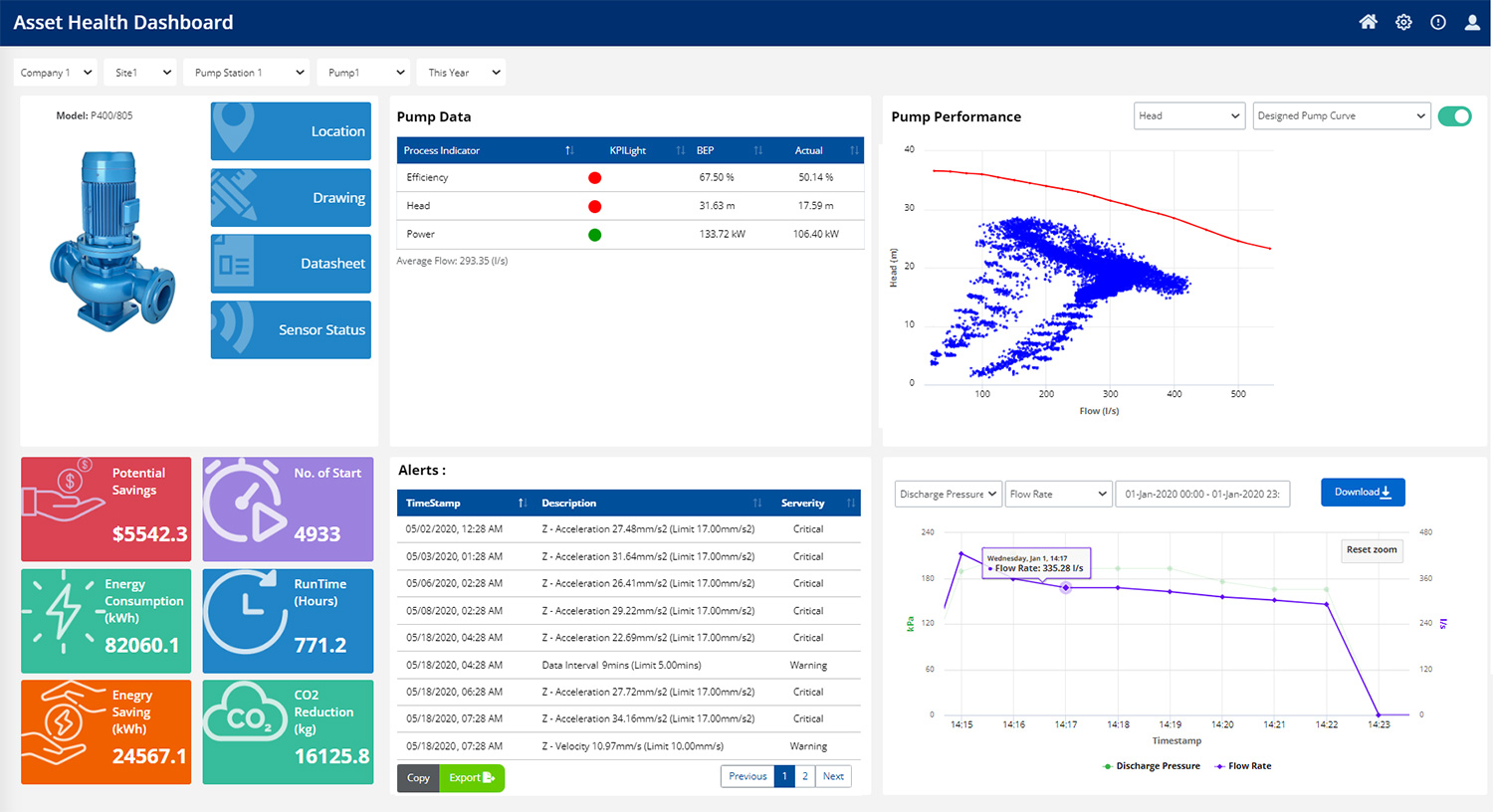

Asset Health Insights is supported by an out-of-the-box framework for data enablement that will improve the health and extend the lifecycle of any asset by monitoring its performance in real-time, making it possible to predict and proactively respond to events before they can happen. The service allows customers to easily model and manage data based on the plant hierarchy defined in the ISA-95 standard. Asset Health Insights is powered by Yokogawa Cloud*1 and is equipped with artificial intelligence (AI)-machine learning (ML) analytics capability.

Development Background

As the adoption of Industry 4.0 technologies continues to gain pace, companies are changing the way they do asset management by introducing cloud-based technologies that can monitor assets from anywhere in the world and optimize their performance in real-time.

Driven by customers' focus on integrated, remote, and increasingly autonomous operations, the company developed Asset Health Insights to make data more visible, integrated, and actionable. It can be used for a variety of purposes, from streamlining operations that rely on manual workflows to more advanced operations that are building a digital society by such means as adopting industrial internet-of-things systems, implementing smart manufacturing, and shifting from on-premises to the cloud. This will also lead to the realization of Industrial Automation to Industrial Autonomy (IA2IA) and smart manufacturing.

With Asset Health Insights, users can consolidate siloed asset data with a unified model that shares information in real-time. This eliminates the need for costly maintenance on well-functioning equipment, improving efficiency and reducing downtime, allowing customers to focus on managing their assets.

Features

- Monitors any asset type

Asset Health Insights can monitor any type of asset, from sensors to pumps, chillers, compressors, turbines, and more. The service will connect to newer and older types of sensors, including those used for pressure, flow, temperature, and vibration. - Combines real-time and/or historical asset data with powerful AI/ML

The combination of real-time asset data and AI/ML helps to predict future events, so advance planning can be done to minimize unnecessary maintenance. It also uses real-time and historical benchmark data to predict signs of failure and suggest its cause. - 360-degree view of operational assets

Asset Health Insights utilizes siloed asset data with a unified model that shares information in real-time and examines each asset and situation for multiple purposes, such as energy, asset performance, and maintenance optimization. With an intuitive interface, the dashboard can present a variety of real-time data from any asset.